Stainless steel is one of the most widely used materials in industries requiring corrosion resistance, strength, and durability. Among the numerous grades of stainless steel, 304 and 316 are the most common. These austenitic stainless steels are similar in many ways, yet they have key differences that affect their weldability, performance, and suitability for specific applications.

This article explores the differences between 304 and 316 stainless steel in the context of welding, including their chemical compositions, welding methods, challenges, and best practices.

1. Overview of 304 and 316 Stainless Steel

304 Stainless Steel

- Composition: ~18% chromium, ~8% nickel

- Properties: Excellent corrosion resistance in most environments, good strength, and formability

- Applications: Kitchen equipment, structural components, tanks, pipes, and architectural features

316 Stainless Steel

- Composition: ~16% chromium, ~10% nickel, and 2–3% molybdenum

- Properties: Superior corrosion resistance, especially to chlorides and marine environments

- Applications: Marine equipment, chemical processing equipment, food processing, and medical instruments

2. Chemical Composition and Its Impact on Welding

The main distinction between 304 and 316 lies in the presence of molybdenum in 316 stainless steel. This addition improves corrosion resistance, especially against chloride-induced pitting and crevice corrosion, making 316 ideal for harsher environments.

However, this also affects the weldability of the material:

- The higher nickel and molybdenum content in 316 can increase the risk of hot cracking in the weld zone.

- 304 is generally easier to weld, especially for beginners or standard applications.

3. Weldability Comparison

| Feature | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Weldability | Excellent | Very Good |

| Risk of Hot Cracking | Low | Medium |

| Corrosion Resistance in Weld Area | Good | Excellent |

| Cost | Lower | Higher |

| Post-Weld Treatment Required | Optional | Recommended for critical applications |

4. Common Welding Processes for 304 and 316

Both 304 and 316 stainless steels are typically welded using the following methods:

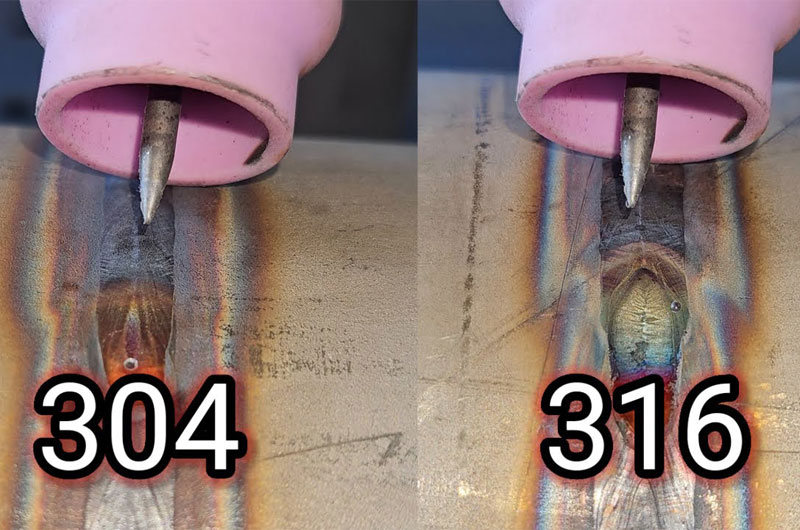

a. TIG Welding (GTAW – Gas Tungsten Arc Welding)

TIG welding offers precise control of heat and filler material, making it perfect for delicate, thin materials and high-precision applications.

- For 304: Use ER308L filler rod

- For 316: Use ER316L filler rod to maintain molybdenum content and corrosion resistance

b. MIG Welding (GMAW – Gas Metal Arc Welding)

MIG is more efficient for larger and thicker sections, offering faster speeds with less operator skill required.

- Shielding gas typically includes Argon with a small percentage of CO₂ or O₂.

c. Stick Welding (SMAW – Shielded Metal Arc Welding)

Best for field welding and outdoor work.

- 308L or 316L electrodes should be used accordingly.

5. Challenges in Welding 304 vs 316

a. Hot Cracking

- 316 stainless steel has a slightly higher susceptibility to hot cracking due to its higher nickel and molybdenum content.

- To prevent this, use low-carbon filler metals like 316L and maintain proper heat input.

b. Sensitization and Intergranular Corrosion

- Both grades can suffer from sensitization when exposed to temperatures between 450°C and 850°C, leading to chromium carbide precipitation at grain boundaries.

- This can be mitigated by:

- Using L-grades (304L and 316L)

- Applying post-weld heat treatment if required

- Avoiding prolonged exposure to sensitizing temperature ranges

c. Distortion and Warping

- Austenitic stainless steels like 304 and 316 have high thermal expansion and low thermal conductivity, leading to greater risk of distortion.

- Use clamping fixtures, sequence welding, and back-stepping to manage this.

6. Filler Material Selection

Selecting the appropriate filler metal is crucial for maintaining corrosion resistance and mechanical properties:

| Base Metal | Recommended Filler Metal |

|---|---|

| 304 | ER308L, E308L-16 |

| 316 | ER316L, E316L-16 |

In dissimilar welding (e.g., welding 304 to 316), use the filler metal of the higher alloy grade, i.e., ER316L, to ensure adequate corrosion protection.

7. Shielding Gas Considerations

Proper shielding gas selection prevents oxidation, porosity, and weld contamination.

- For TIG Welding: 100% Argon or Argon + small % of Hydrogen/Helium

- For MIG Welding: Argon + 1–2% O₂ or CO₂

For both 304 and 316, gas purity and adequate shielding coverage are essential to produce clean, strong welds.

8. Surface Preparation and Post-Weld Cleaning

To ensure weld quality and corrosion resistance:

- Clean all surfaces to remove oil, grease, and oxides.

- Use dedicated stainless steel brushes and grinding tools to prevent carbon steel contamination.

- Pickling and passivation after welding help restore the protective chromium oxide layer.

Post-weld cleaning is especially critical for 316 stainless steel in corrosive or marine applications.

9. Cost Implications

While both materials are weldable, 316 stainless steel is more expensive due to:

- Higher alloy content

- More meticulous welding and post-weld treatment

- Use in specialized applications requiring strict corrosion resistance

Welding 316 often demands higher skilled labor and more costly filler materials, which should be factored into project planning.

10. Applications Based on Welded Performance

| Application | Preferred Grade |

|---|---|

| Indoor structures | 304 |

| Food processing equipment | 304 or 316 (depending on exposure) |

| Marine or coastal equipment | 316 |

| Chemical tanks or pipes | 316 |

| General fabrication | 304 |

| Medical tools | 316 |

Conclusion

304 and 316 stainless steels are both excellent materials for welding, but they cater to different requirements based on environmental conditions, corrosion resistance, and mechanical stress.

Choosing between 304 and 316 stainless steel for welding should consider factors such as application environment, corrosion exposure, budget, and required post-weld treatments. With the right techniques, filler materials, and precautions, both grades can be welded successfully to deliver long-lasting and reliable results.