Custom Sheet Metal Fabrication

- Our advanced capabilities include shearing, precise cutting, bending, stamping, punishing, welding and surface finishing of sheet metal to meet your exact specifications.

- From rapid prototyping to full production runs, we deliver excellence in every project.

- Small to large and heavy components

- Supports almost metal types

- Linear Dimension Tolerance: ±0.004" (0.10mm), ISO 2768-mK Standard

- Bend to Hole Tolerance: ±0.008" (0.20mm), ISO 2768-mK Standard

- Angular Tolerance: +/- 0.5 degree

- Multiple Finishing Options

Sheet Metal Fabrication Abilities

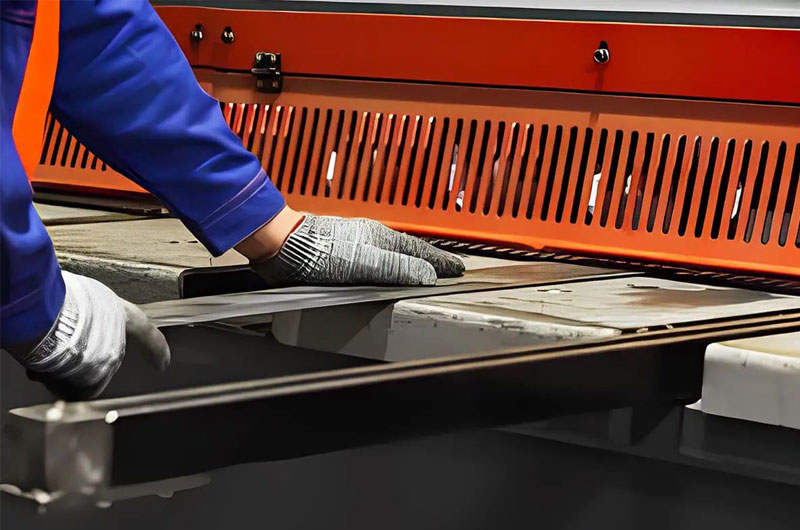

Shearing

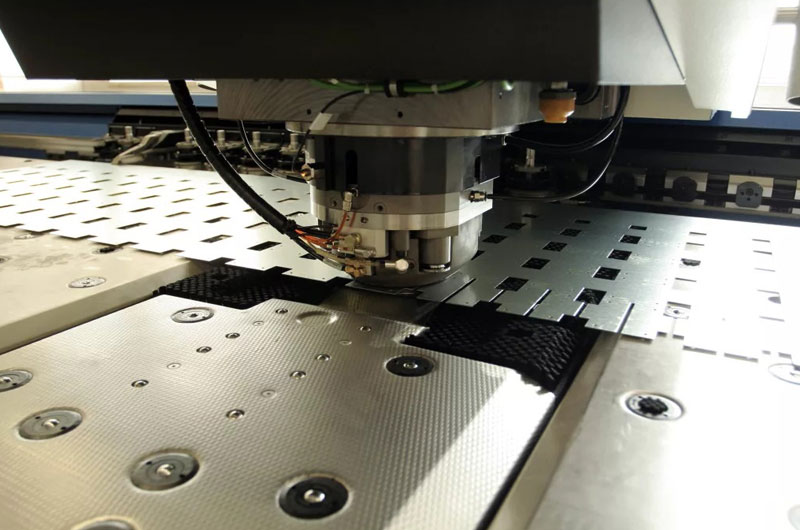

Cutting

Bending

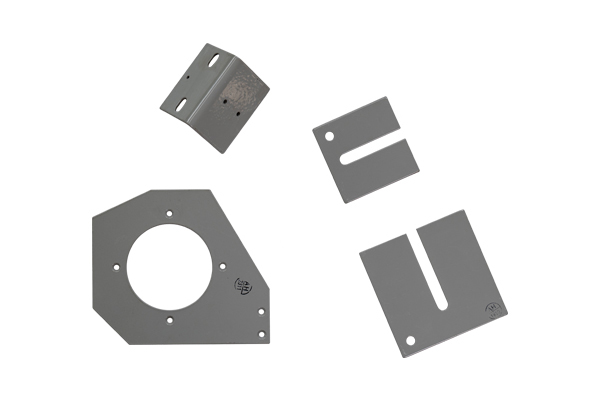

Stamping

Punching

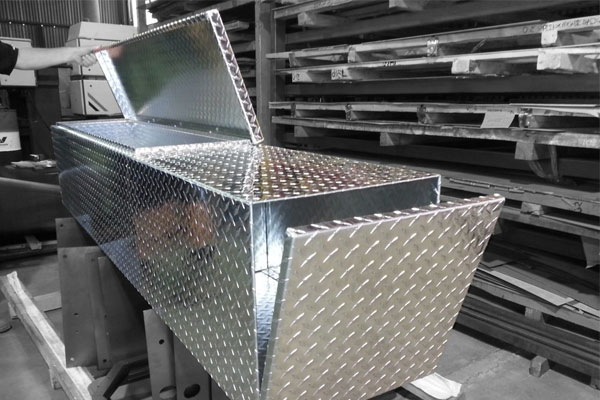

Welding

It is often the final step in sheet metal fabrication, by applying MIG, TIG, or spot welding techniques to join metal parts together, creating a permanent bond between parts and ensuring the structural integrity.

Supported Sheet Metal Materials

| Aluminum | 1100-H14 Aluminum Alloy | 5052-H32 Aluminum Alloy | 6061 Aluminum Alloy | 7075 Aluminum Alloy | ||

| Stainless Steel | 301 Stainless Steel | 303 Stainless Steel | 304 Stainless Steel | 316 Stainless Steel | 430 Stainless Steel | |

| Steel | DC01 Carbon Steel | 1018 Steel | 1020 Steel | Galvanized Steel | Cold Rolled Steel | Hot Rolled Steel |

| Copper | 260 Copper | 1100 Copper | 110 Copper | 101 Copper | ||

| Bronze | Bronze 220 | Bronze 510 | ||||

| Nickel Alloys | Inconel 600 | Inconel 625 | Monel 400 | Nickel 200 | Nickel 400 | |

| Titanium | Titanium Grade 2 | Titanium Grade 4 | Titanium 6Al-4V Grade 5 |

Powder Coating

A durable finish applied as a dry powder, suitable for iron, aluminum, and stainless steel.

Anodizing

An electrolytic process that enhances aluminum’s corrosion resistance and surface hardness, improving durability and aesthetics.

Bead Blasting

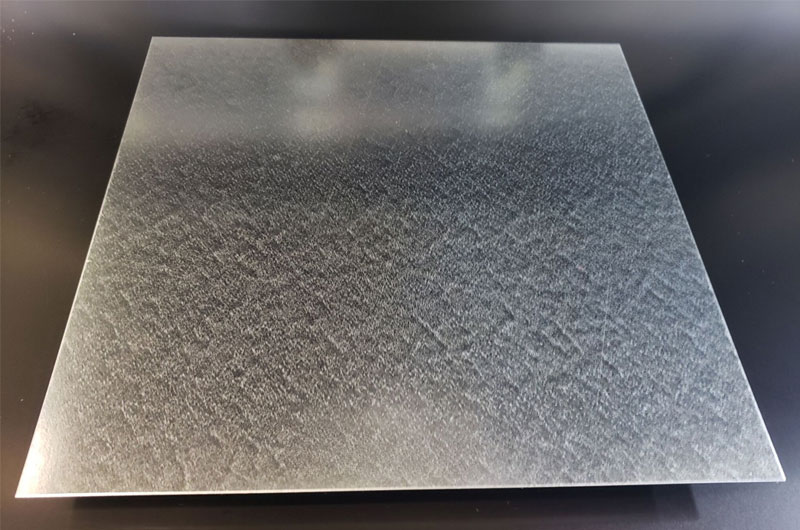

A cleaning method using abrasive beads to achieve a textured surface on steel, aluminum, and stainless steel.

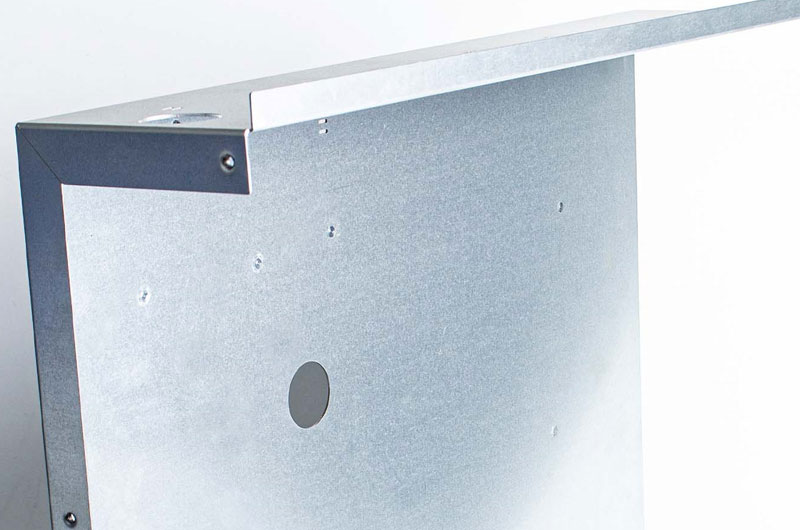

Galvanizing

A zinc coating process that protects steel from rust and corrosion, extending the lifespan of iron and steel components.

Electroplating

A technique that deposits a metal layer, such as nickel or chrome, on various substrates for enhanced appearance and protection.

Plating

The application of a metal coating to a substrate for decorative or protective purposes, commonly used on steel and aluminum.

Passivation

Enhances corrosion resistance by treating stainless steel with acid, creating a protective oxide layer.

Sheet Metal Finishing

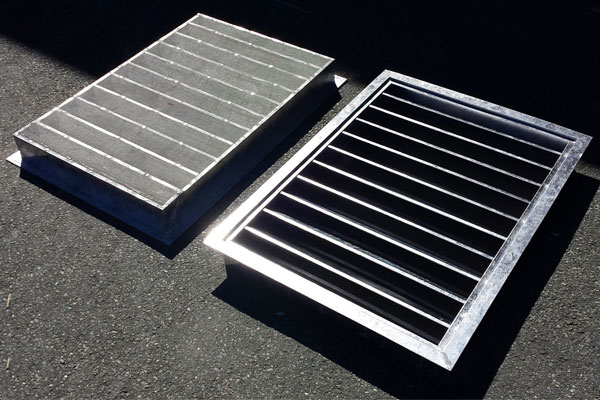

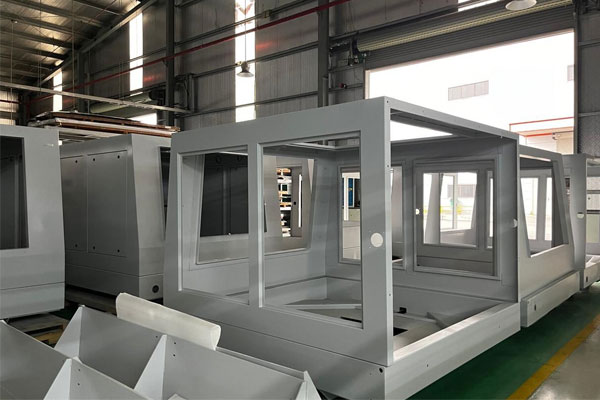

Our Sheet Metal Fabricated Parts

Applications

HVAC Systems

Air Conditioning

Aerospace / Aircraft

Electronics

Automotive

Solar Panels

Create mounting brackets, frames, supports, and housings for solar panels.