A key component of the welding process is the filler metal, a material added to the weld joint to aid in the fusion and strengthen the final bond. Filler metals are essential components in welding, significantly influencing the weld’s strength, durability, corrosion resistance, and overall quality.

This article explores the critical role of filler metals in welding quality, their types, selection criteria, and how they influence the performance of welded structures.

What Are Filler Metals?

Filler metals are consumable materials used in welding to bridge the gap between the base metals being joined. They melt during the metal welding process and combine with the molten base metals to create a strong, cohesive joint. To ensure a quality weld, the filler metal’s composition must closely match the base materials to prevent issues such as brittleness, cracking, or corrosion.

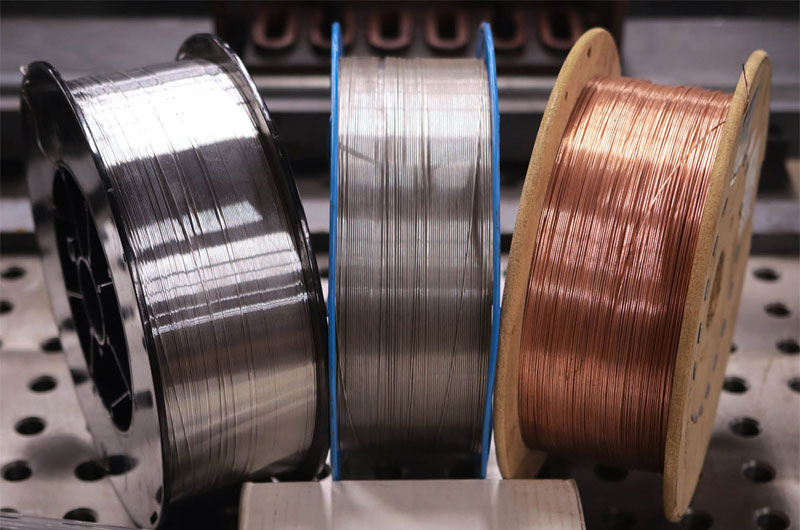

Filler metals are typically supplied in different forms, such as wires, rods, or electrodes, depending on the welding method being used: Gas Metal Arc Welding (GMAW/MIG), Shielded Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW/TIG), or Flux-Cored Arc Welding (FCAW).

Importance of Filler Metals in Welding Quality

The quality of a weld is defined by its mechanical properties (like tensile strength and toughness), resistance to environmental damage, appearance, and the absence of defects such as porosity or cracks. Filler metals have a significant influence on each of these parameters:

1. Mechanical Properties

The mechanical properties of the weld metal are directly influenced by the filler metal’s composition. Using a filler that matches or exceeds the strength of the base metal ensures a durable joint. For instance, in structural applications, filler metals with high tensile strength are crucial to prevent joint failure under stress.

2. Metallurgical Compatibility

Chemical compatibility between filler metals and base metals is critical for maintaining weld integrity and performance. Incompatible fillers can lead to the formation of brittle intermetallic compounds, segregation of elements, or unwanted phases in the weld zone. This compatibility ensures proper metallurgical bonding and minimizes the risk of weld defects.

3. Corrosion Resistance

In corrosive environments (e.g., chemical plants, marine structures), the filler metal must have corrosion resistance properties that match or exceed the base metals. For example, stainless steel filler metals are used to maintain corrosion resistance when welding stainless steel components.

4. Crack Resistance

Filler metals with appropriate levels of elements like nickel, chromium, or molybdenum help prevent cracking in the heat-affected zone (HAZ) and weld metal. These elements enhance ductility and toughness, particularly in low-temperature service conditions.

5. Weldability and Appearance

Some filler metals are engineered to provide better weld puddle control, less spatter, and a cleaner bead appearance. This improves weld aesthetics and reduces the need for post-weld cleaning or finishing.

Types of Filler Metals

Filler metals are classified by their form and alloy composition. Here are the most common categories:

1. Mild Steel Filler Metals

Widely used in construction and general fabrication, mild steel fillers like ER70S-6 (for MIG welding) or E6013 (for SMAW) offer a good balance of strength, ductility, and weldability.

2. Stainless Steel Filler Metals

Used when corrosion resistance is vital. Common grades include ER308L and ER316L for welding austenitic stainless steels.

3. Aluminum Filler Metals

Popular in aerospace and automotive industries, aluminum fillers like ER4045 and ER5356 are used to weld aluminum and its alloys. They must be carefully matched to avoid hot cracking and porosity.

4. Nickel-Based Filler Metals

Certain filler metals are specifically suited for welding alloys that must withstand high temperatures and corrosive environments, making them ideal for use in industries like chemical processing and power generation.

5. Flux-Cored Wires

Used in FCAW, these filler metals contain a flux within a hollow wire. The flux stabilizes the arc and may provide shielding gas or alloying elements, improving productivity and weld quality.

Filler Metal Selection Criteria

Selecting the right filler metal is crucial for optimal weld performance. Key factors to consider include:

1. Base Metal Type and Thickness

The filler metal must be compatible with the composition and thickness of the base metal. For dissimilar metal welding, special fillers designed for metallurgical compatibility must be used.

2. Welding Process

Different welding processes require different forms of filler metals. For instance, SMAW uses stick electrodes, while MIG welding uses continuous wire feeds.

3. Service Conditions

When selecting filler metals, it is important to consider factors such as service temperature, mechanical loading, and exposure to corrosive elements. For example, structures exposed to cryogenic temperatures require fillers with excellent low-temperature toughness.

4. Code and Standard Requirements

Projects governed by standards (e.g., AWS, ASME, ISO) specify acceptable filler metals for particular applications, including certifications and testing requirements.

5. Post-Weld Treatments

If the weld will be heat-treated or machined, the filler metal must be able to withstand such processes without degrading performance.

Common Welding Defects Related to Filler Metals

Improper filler metal selection or handling can lead to defects that compromise weld quality:

- Porosity: Caused by contamination or moisture in the filler metal.

- Cracking: Occurs when the filler metal is too brittle or incompatible.

- Lack of Fusion: May result from low fluidity or incorrect heat input for the chosen filler.

- Undercutting and Excessive Spatter: Often due to mismatched filler and poor technique.

Using high-quality, properly stored filler metals and following correct welding procedures can minimize these risks.

Common Applications and Case Studies

- Structural Steel Construction: Buildings and bridges rely on E7018 low-hydrogen electrodes for structural girders. Their balance of strength (~70 ksi) and crack resistance under paint systems makes them industry staples.

- Pressure Vessels and Pipelines: Stainless steel tanks for chemical storage employ 316L filler wire to resist chloride-induced stress corrosion cracking. Welds meet ASME Section VIII requirements, ensuring safety under high pressure.

- Aerospace Components: High-temperature nickel alloys (e.g., Inconel 718) require matching filler rods for turbine blades. Precise control of composition avoids phase instability that could compromise creep resistance.

- Automotive Manufacturing: Automakers use aluminum MIG wires tailored for 5xxx and 6xxx series alloys. The right filler and shielding gas minimize porosity and ensure crash-worthy performance.