In welding, the selection of the correct electrode is crucial for achieving strong, clean, and defect-free welds. Each metal type has unique chemical and physical properties that require specific electrode characteristics to ensure proper bonding. Choosing the wrong electrode can result in poor penetration, cracking, or even complete weld failure.

In this article, we will explore how to choose the right welding electrode for different metals, considering factors like metal type, thickness, position, and desired weld characteristics.

Understanding Welding Electrodes

Welding electrodes, or welding rods, serve two key functions:

- Conducting current to generate the arc that melts both the electrode and the workpiece.

- Adding filler material to the weld pool to help fuse the base metals.

Electrodes can be classified into two types:

- Consumable electrodes (used in processes like Stick and MIG welding) that melt during the weld.

- Non-consumable electrodes (used in TIG welding), which do not melt but use a separate filler rod.

For this guide, we’ll focus primarily on consumable electrodes used in Shielded Metal Arc Welding (SMAW), or Stick Welding, one of the most common methods for welding a wide variety of metals.

Key Factors in Electrode Selection

Before diving into electrode types, it’s important to consider a few basic factors:

1. Base Metal Type

Each metal (e.g., mild steel, stainless steel, aluminum, cast iron) has unique properties such as melting point, thermal conductivity, and oxidation behavior. These influence electrode selection.

2. Metal Thickness

Thicker metals generally require higher amperage and deeper penetration, which means using a larger diameter electrode and a specific flux composition.

3. Welding Position

Certain electrodes perform better in vertical or overhead welding because they offer superior slag control and puddle stability.

4. Polarity and Current Type

Electrodes are rated for use with AC, DC, or both. Using the wrong current type can lead to arc instability or poor fusion.

5. Mechanical Requirements

Tensile strength, ductility, and toughness of the weld must match the job’s demands (e.g., structural vs decorative).

Common Electrodes and Their Applications by Metal Type

1. Mild Steel (Carbon Steel)

Recommended Electrodes:

- E6010 – Deep penetration, good for pipe welding and dirty/rusty surfaces.

- E6011 – Similar to E6010 but usable with AC. Ideal for general-purpose repair.

- E7018 – Low-hydrogen electrode with a smooth arc, minimal spatter, and excellent strength. Perfect for structural work.

Selection Tip:

Use E6010/E6011 for root passes and E7018 for cap passes or strength-critical applications.

2. Stainless Steel

Recommended Electrodes:

- E308L-16 – Common for 304 stainless steel. Low carbon to prevent carbide precipitation.

- E309L-16 – Used for welding stainless steel to carbon steel.

- E316L-16 – Used for 316 stainless, particularly in corrosive environments.

Selection Tip:

Match the electrode alloy to the stainless base metal. Use low-carbon versions (indicated by “L”) to reduce intergranular corrosion.

3. Aluminum

Aluminum is typically welded using TIG or MIG, not Stick, due to oxidation and difficulty in controlling the arc.

TIG Electrode:

- Use 2% Thoriated Tungsten (EWTh-2) for DC welding.

- Use Pure Tungsten (EWP) or Zirconiated Tungsten (EWZr) for AC welding.

Filler Metal:

- ER4045, ER5356, ER4043 are common aluminum filler rods.

Selection Tip:

Always clean the aluminum surface of oxide before welding. Choose AC current with high-frequency start for best results.

4. Cast Iron

Cast iron is brittle and difficult to weld. Preheating and slow cooling are usually required.

Recommended Electrodes:

- Nickel-based electrodes (ENi-CI, ENiFe-CI) – Good for machinability and reduced cracking.

- Steel-core electrodes – Less expensive but more prone to cracking and harder to machine.

Selection Tip:

Use ENiFe-CI for high-strength applications. Always follow slow cooling and peening techniques.

5. Galvanized Steel

Galvanized coatings emit toxic fumes, so safety precautions are essential.

Recommended Electrodes:

- E6011 or E6010 – Their aggressive arc can burn through the zinc coating.

Selection Tip:

Grind off the galvanized layer near the weld zone when possible. Use proper ventilation.

6. High-Strength Low-Alloy (HSLA) Steel

These steels offer strength and toughness but require compatible electrodes to avoid brittle welds.

Recommended Electrodes:

- E7018-A1, E8018-C1 – Designed for alloy steels with added strength and notch toughness.

Selection Tip:

Match tensile strength of the electrode with the base metal. Preheat as needed.

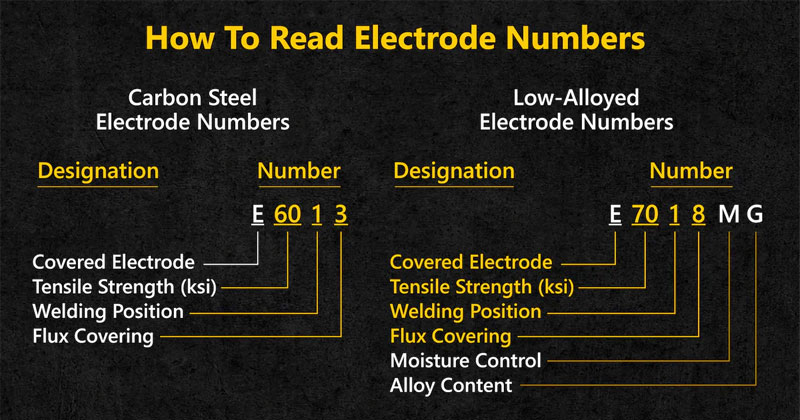

Electrode Coding System (AWS)

The American Welding Society (AWS) classifies electrodes using a standard code:

Example: E7018

- E: Electrode

- 70: Minimum tensile strength (70,000 psi)

- 1: Welding position (1 = all positions)

- 8: Type of flux coating and current

Understanding this helps in comparing and selecting suitable electrodes for any project.

Electrode Storage and Handling

Moisture can ruin low-hydrogen electrodes like E7018, leading to hydrogen-induced cracking.

Tips:

- Store electrodes in a dry environment.

- Use rod ovens to keep E7018 rods at 250–300°F (120–150°C).

- Avoid touching electrodes with bare hands to prevent contamination.

Summary Chart

| Metal Type | Recommended Electrodes | Notes |

|---|---|---|

| Mild Steel | E6010, E6011, E7018 | Choose based on position and strength needs |

| Stainless Steel | E308L-16, E309L-16, E316L-16 | Match electrode alloy to base metal |

| Aluminum | TIG: ER4045, ER5356 + Pure Tungsten | Use AC current, clean thoroughly |

| Cast Iron | ENi-CI, ENiFe-CI | Preheat and slow-cool to reduce cracking |

| Galvanized Steel | E6010, E6011 | Remove zinc coating if possible |

| HSLA Steel | E7018-A1, E8018-C1 | Match tensile strength, preheat as needed |