Cutting brass and copper requires careful consideration of their physical properties and the intended application. The choice of cutting method can significantly affect productivity, part accuracy, edge quality, and material waste.

This article explores various cutting methods for brass and copper, along with guidance on selecting the most suitable one.

Understanding Brass and Copper Properties

Before selecting a cutting method, it’s important to understand the characteristics of brass and copper:

- Brass is an alloy of copper and zinc, known for its machinability and strength. The addition of zinc makes it harder than pure copper but also more brittle in certain grades.

- Copper is a soft, ductile, and highly conductive metal. Its softness makes it prone to deformation and burr formation during cutting, requiring careful handling.

Both metals are thermally and electrically conductive, and they are susceptible to heat buildup during mechanical or thermal cutting, which can affect cut quality and tool life.

Common Cutting Methods for Brass and Copper

1. Shearing

Best for: Straight-line cuts in sheets and plates

Pros: Fast, cost-effective, minimal heat generation

Cons: Limited to straight cuts, risk of edge distortion if not clamped properly

Shearing is ideal for cutting brass or copper sheet metal in high-volume applications. Guillotine or bench shears deliver clean cuts with minimal material waste.

2. Sawing (Band Saw or Circular Saw)

Best for: Bars, rods, and thick plates

Pros: Accurate cuts, suitable for thick material, low-cost tooling

Cons: May leave burrs, slower than thermal methods

A fine-toothed blade with proper coolant is recommended to prevent overheating. Brass cuts well with carbide-tipped saws, while copper’s softness can cause blade clogging without adequate chip removal.

3. Laser Cutting

Best for: Intricate shapes in thin to medium sheets

Pros: High precision, no physical contact, clean edges

Cons: High reflectivity of copper/brass can reduce efficiency, potential heat-affected zones

Fiber lasers, especially those with power modulation and high-speed scanning, are more effective than CO₂ lasers for cutting reflective metals like brass and copper.

4. Waterjet Cutting

Best for: Thick materials and heat-sensitive applications

Pros: No thermal distortion, smooth edges, supports complex geometry

Cons: Slower than laser cutting, higher operating costs

Waterjet cutting is ideal when heat-affected zones must be avoided. It can cut copper and brass up to several inches thick with high precision.

5. Plasma Cutting

Best for: Medium to thick sheets

Pros: Fast cutting speed, portable equipment

Cons: Poor performance on copper and brass due to conductivity, less precise than laser/waterjet

Although suitable for some brass alloys, plasma cutting is not typically recommended for copper because its high conductivity dissipates the arc energy.

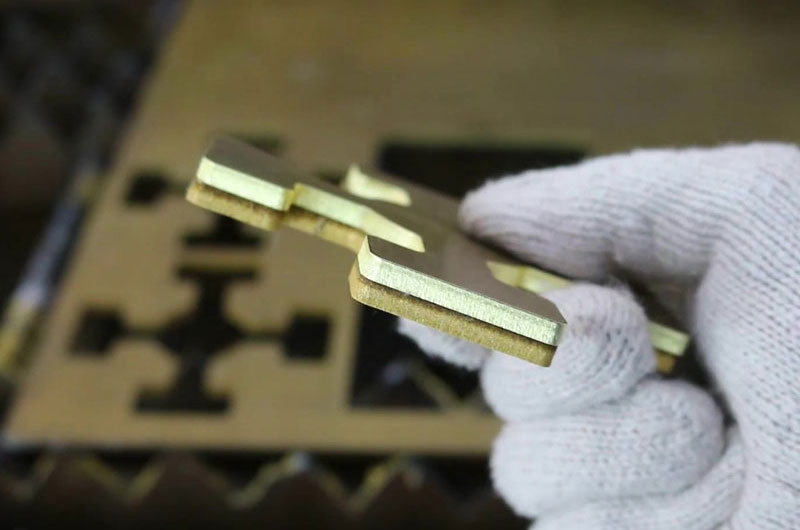

6. CNC Machining (Milling or Routing)

Best for: Detailed parts, prototyping, and small-batch production

Pros: Extremely accurate, supports 3D features

Cons: Slower, tool wear on soft copper, burr formation

CNC routers and mills with sharp, coated tools and high-speed spindles are ideal for cutting precise parts from brass or copper plates.

How to Choose the Right Cutting Method

When deciding which method to use, consider the following factors:

| Criteria | Recommendation |

|---|---|

| Material Thickness | Thin sheets: laser or waterjet. Thick plates: sawing or waterjet. |

| Edge Quality | Waterjet and laser offer clean edges. Sawing may need deburring. |

| Production Volume | High volume: shearing or CNC punching. Low volume: CNC machining or waterjet. |

| Part Complexity | Intricate geometry: laser, waterjet, or CNC milling. |

| Budget | Low-cost: shearing or sawing. High-precision jobs: laser or waterjet. |

| Heat Sensitivity | Avoid thermal methods for copper; waterjet or mechanical cutting preferred. |

Tips for Optimal Cutting

- Tool Selection: Use sharp tools with proper rake angles to minimize burrs.

- Coolant Use: Essential in machining or sawing to prevent heat buildup.

- Workholding: Ensure secure clamping to avoid vibration or movement during cutting.

- Post-Processing: Deburring or surface finishing may be required, especially for sawn or machined parts.