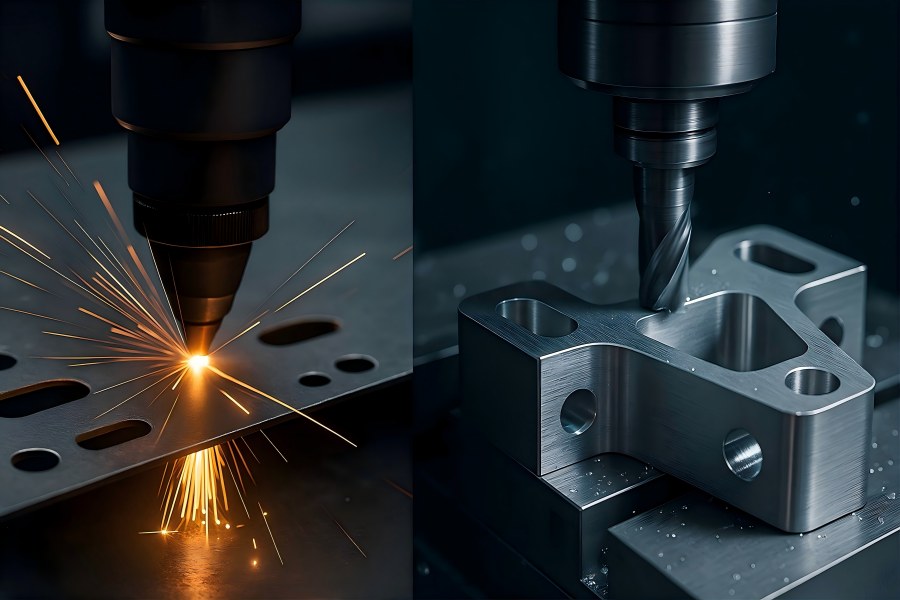

Custom brackets hold sensors, support panels, align shafts, and make assemblies serviceable. The best way to customize them usually comes down to two processes: laser cutting (for fast, precise 2D profiles in sheet) and CNC machining (for high-precision 3D features, threads, and thicker sections).

This guide explains how each process works, what accuracy and finishes to expect, how costs scale with quantity, and when a hybrid flow wins.

What “Customized Brackets” Usually Mean

Most brackets start as flat profiles with holes and slots, then gain features that tailor them to a job: countersinks so fasteners sit flush, threads for direct mounting, stiffening pockets, edge chamfers to remove sharp corners, and sometimes precision datums for repeatable assembly.

Some jobs use thin sheet (1–6 mm) with bends; others demand thick, rigid blocks or lugs (10–40 mm) that carry serious loads. Matching the process to the bracket’s thickness, precision, and features is the heart of good DFM.

How the Two Processes Work

Laser cutting uses a focused beam to melt/vaporize material along a programmed path. It excels at 2D geometry in sheet metal (steel, stainless, aluminum, brass). Modern fiber lasers cut fast, leave clean edges, and minimize heat-affected zones (HAZ), especially on thin stock.

CNC machining removes material with rotating tools in three to five axes. It creates accurate 3D features (pockets, bosses), excellent hole quality, true flat faces, functional threads, and cosmetic chamfers/fillets on plate or block stock as well as laser-cut blanks.

In practice, many brackets are laser-cut blanks + secondary machining (tapping, countersinking, reaming). That hybrid often hits the best balance of speed, precision, and cost.

Dimensional Accuracy and Fit

For bracket fit—bolt alignment, slot clearance, datum true position—accuracy matters.

Positional accuracy: Laser cutting typically holds ±0.10 mm on thin sheet; on thick sections or very small features it may relax to ±0.15–0.25 mm. CNC positional accuracy of ±0.02–0.05 mm is routine on properly fixtured parts.

Hole quality: Laser holes are round and fast to make but can show taper and slight out-of-roundness on thicker stock. CNC-drilled/reamed holes are straighter and tighter and readily controlled to H7/H8-like fits with reaming.

Kerf & corner detail: Laser kerf is ~0.10–0.20 mm, allowing crisp outside corners and fine internal features (within thermal limits). CNC internal corners are limited by tool radius; specifying small radii may require micro end mills and higher cycle times.

Typical Accuracy

| Metric | Laser Cutting (Sheet 1–6 mm) | CNC Machining (Plate/Block) |

| Positional tolerance (typical) | ±0.10 mm | ±0.02–0.05 mm |

| Hole diameter tolerance (typical) | ±0.10–0.20 mm | ±0.01–0.03 mm (drill/ream) |

| Edge taper | 0.1–1.0° (thickness-dependent) | ~0° (milled) |

| Surface finish (edge) | Ra 3–10 µm | Ra 1–3 µm (finish pass) |

| Minimum practical slot width | ≈ material thickness (quality-driven) | Tool dia. (e.g., 1–3 mm common) |

| Heat-affected zone | ~0.05–0.4 mm | None |

Edge Quality And Post-Processing

Laser edges are smooth and consistent, especially on thin stainless and mild steel. On thicker stock and aluminum, you may see minor dross that deburrs quickly. CNC-milled edges are burr-free with controllable chamfers or radii and better cosmetic consistency across faces.

If paint or powder coat is planned, both processes benefit from a light deburr/edge break; CNC enables precise chamfer size callouts that painters and assemblers appreciate.

Material and Thickness Range

Laser cutting: Outstanding on sheet and plate. Mild steel to ~25 mm (machine-dependent), stainless to ~16–20 mm, aluminum often to ~12–15 mm with fiber lasers. Reflective alloys (Al, Cu, brass) are now routine on modern fiber systems. Very thick sections see slower speed, larger HAZ, and more taper.

CNC machining: Works across thin to very thick stock, including aluminum plate (e.g., 20–50 mm), alloy steels, titanium, and plastics. It’s the go-to for thick, rigid brackets, complex 3D shapes, and precision mating faces.

Speed, Lead Time, and Lot Size Economics

Laser shines on program-and-go 2D shapes with minimal fixturing; programming nests to maximize sheet utilization. Changeovers are fast.

CNC requires fixturing, toolpaths, and more detailed programming, making its setup a larger share of unit cost at low volumes—but CNC wins where features demand it.

Illustrative Cost Comparison (Simple Flat Bracket)

Assumptions for a 100 × 100 × 3 mm mild steel bracket with 6 holes and 2 slots (no threads; coating not included).

Laser cutting: $60 setup; $1.50/min cutting; 0.5 min/part; $0.30 deburr/part; $0.50 material/part.

CNC machining: $120 setup; $2.50/min cycle; 6 min/part; $0.20 tooling/part; $0.50 material/part.

| Quantity | Laser: Total Cost | Laser: Cost/Part | CNC: Total Cost | CNC: Cost/Part |

| 1 | $61.55 | $61.55 | $135.70 | $135.70 |

| 10 | $75.50 | $7.55 | $277.00 | $27.70 |

| 50 | $137.50 | $2.75 | $905.00 | $18.10 |

| 200 | $370.00 | $1.85 | $3,260.00 | $16.30 |

Takeaway: For simple flat parts without threads, laser cutting dominates unit cost—especially above very small quantities. But as soon as you add countersinks, precise H7 holes, or threads, expect a hybrid flow (laser + CNC) to be the best value.

Feature Capability For Brackets

Hole And Slot Geometry

Laser: Fast for many holes/slots; small holes can run hot on thick plate (taper and recast). A common rule of thumb is minimum hole ≈ material thickness for best quality. For bolt holes that must align with tight stack-ups, consider post-machining a few locating holes.

CNC: Superior roundness and cylindricity; easy to hit tight callouts on bolt patterns or reamed dowel holes.

Threads And Countersinks

Laser: Cannot create threads or countersinks. You’ll laser the pilot and CNC tap/countersink afterward (or use PEM nuts if sheet is thin).

CNC: Direct drilling, tapping (cut or form), countersinking at controlled angles and depths. Great for load-bearing, serviceable fastener interfaces.

Pockets And Weight Reduction

Laser: 2D only. Weight reduction via cutouts is fast and cheap on sheet brackets.

CNC: 3D pockets and ribs that tune stiffness-to-weight on thick brackets; machined pockets also provide datum faces for repeatable assembly.

Edge Chamfers and Fillets

Laser: Edge is “as cut” unless you add a deburr step. Edge breaks can be added by tumbling; precise chamfers require machining.

CNC: Controlled chamfers/fillets everywhere they’re needed (typical 0.5–1.0 mm chamfers for safety and coating).

Tolerancing and GD&T Considerations

- Datums: If your bracket locates a precision sensor, define machined datums (faces or holes) and keep laser-only features non-critical.

- True position: Keep tight true-position callouts (≤ ±0.05 mm) for CNC’d holes; allow looser positions on laser-only features that simply clear bolts.

- Flatness: Sheet parts may move slightly from residual stress and heat. CNC skim passes can produce flat, parallel faces on thick parts or add relief pockets so the bracket sits flush.

Strength and Heat Effects

Laser HAZ is thin, but on high-carbon steels and thick sections it can slightly change microstructure at the cut edge. For fatigue-sensitive brackets, radius internal corners, deburr thoroughly, and specify a post-cut edge condition (e.g., grind-break sharp corners).

CNC removes material mechanically, so there’s no HAZ—useful for high-cycle load paths and precisely loaded lugs.

Surface Finish and Aesthetics

Laser edges are uniform and dark-etched on carbon steel, bright on stainless/aluminum. After powder coating, edge differences disappear, but pre-coat edge breaks improve paint wrap and chip resistance.

CNC faces can achieve low Ra finishes with consistent sheen. If the bracket is visible, machined chamfers and face patterns elevate perceived quality.

When Laser Wins

- Thin-to-moderate sheet brackets with many holes/slots.

- Medium to high quantities where setup amortization matters.

- Designs where no threads/countersinks are needed (or where you’ll add PEM hardware).

- Fast-turn prototypes where 2D geometry is the main task and you can accept ±0.10–0.20 mm fit.

When CNC Wins

- Thick, highly loaded brackets (10–40 mm) needing tight tolerances and flat mating faces.

- Parts with threads, countersinks/counterbores, precision dowel holes, or 3D pockets.

- Situations requiring tight GD&T (true position, perpendicularity, flatness) across multiple faces.

- Visible components where cosmetic machining and controlled chamfers are selling points.

The Hybrid Workflow Most Shops Use

The most economical route for many brackets is: laser cut the blank → form (if needed) → CNC critical features (tapping, countersinks, precision holes, skim faces). You get laser’s speed on non-critical geometry and CNC’s precision where it matters, without machining every edge.

Example Hybrid Flow Data Point

A 3 mm stainless bracket with 10 clearance holes and 2 M6 threads, Qty = 100:

- Laser: 0.6 min/part, $1.50/min → $0.90 + $0.30 deburr + $0.70 material ≈ $1.90/part

- CNC secondary (tap 2 holes + countersink 4): 1.2 min/part at $2.50/min + $0.15 tooling ≈ $3.15/part

- Total variable ≈ $5.05/part (+ modest setups). Still far below full-CNC from plate.

Two Short Case Studies

Thin Sensor Mount, 2,000 Pieces

1.5 mm 304 stainless, 8 clearance holes, 2 slotted adjustment holes, cosmetic powder coat.

- Process: Laser cut nest on large sheets, tumble deburr, bend, insert PEM nuts.

- Why: Unit cost and takt time win. No CNC needed; threaded PEMs give strong threads without tapping.

Heavy Equipment Lug Bracket, 5 Pieces

20 mm 7075-T6, two reamed Ø10 dowel holes at tight true position, four M12 threads, pocketed to reduce weight.

- Process: CNC from plate with roughing + finish passes, thread mill/tap, ream dowel holes, add chamfers.

- Why: Precision and thickness drive full-CNC; laser would be slow, leave taper, and still need machining.

A Quick Decision Matrix

| Situation | Recommended Path | Rationale |

| Thin sheet (< 6 mm), many holes/slots, no threads | Laser-only | Lowest cost/part, fastest lead time |

| Thin sheet with a few threads/countersinks | Laser + CNC secondary or laser + PEM | Laser for profile; machining or hardware adds function |

| Thick plate (≥ 10 mm) with precision features | CNC-only | Tight GD&T, no HAZ, flat faces |

| Visible bracket with cosmetic chamfers | Laser + CNC edge/face touches | Combine speed and finish |

| Very small lot, complex 3D features | CNC-only | Setup amortization less relevant; precision matters |

| Very large lot, simple 2D | Laser-only (possibly turret punch) | Throughput and nesting efficiency dominate |