Our Blogs

Custom brackets hold sensors, support panels, align shafts, and make assemblies serviceable. The best way to customize them usually comes […]

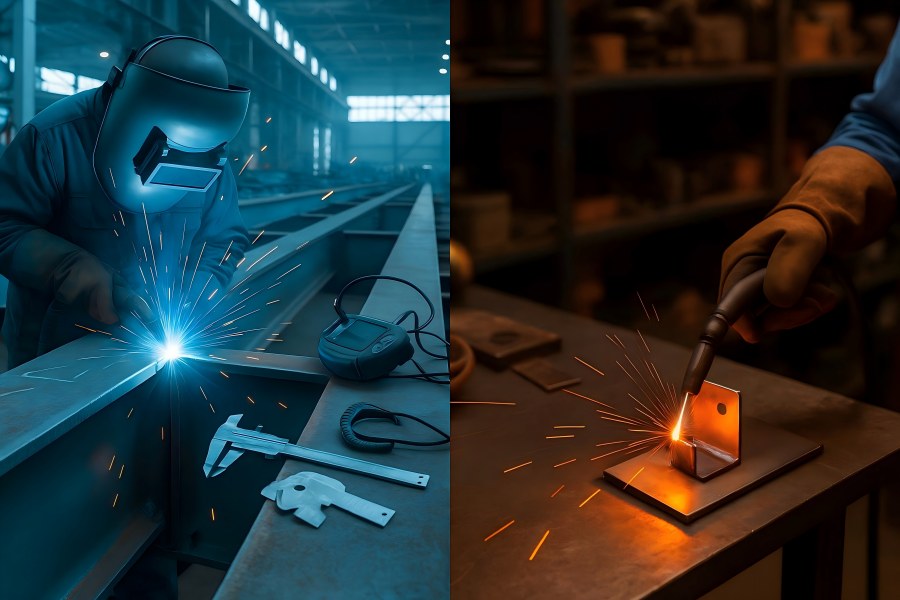

Structural and “standard” welding reflect different intent levels. Structural welding is engineered to carry defined loads for decades, using codes, […]

Selecting a structural welding partner is a high-leverage decision. The right shop delivers safe, code-compliant weldments that arrive on time […]

Heating, Ventilation, and Air Conditioning (HVAC) systems are integral to indoor environmental control, and at the heart of every efficient […]

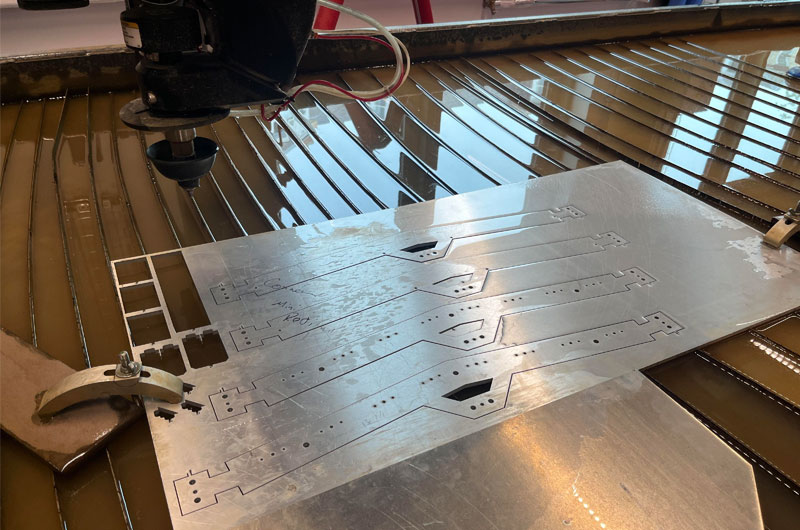

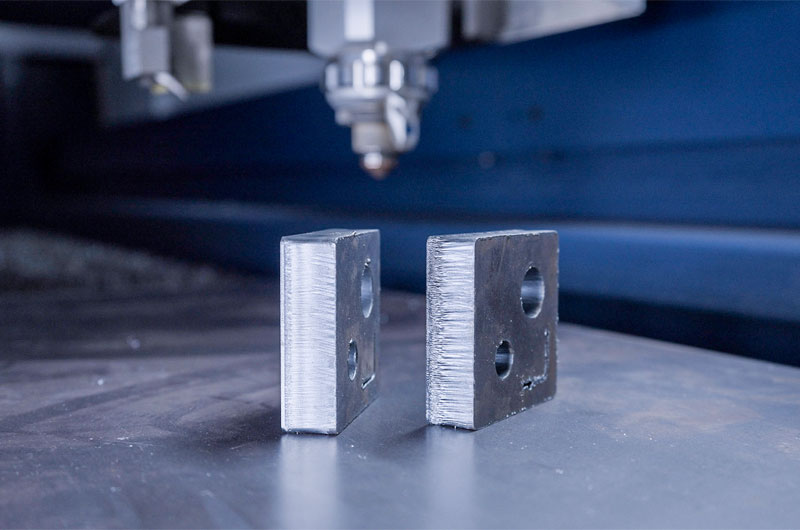

Flatness is a fundamental property of sheet metal that plays a critical role in the success of cutting operations. Whether […]

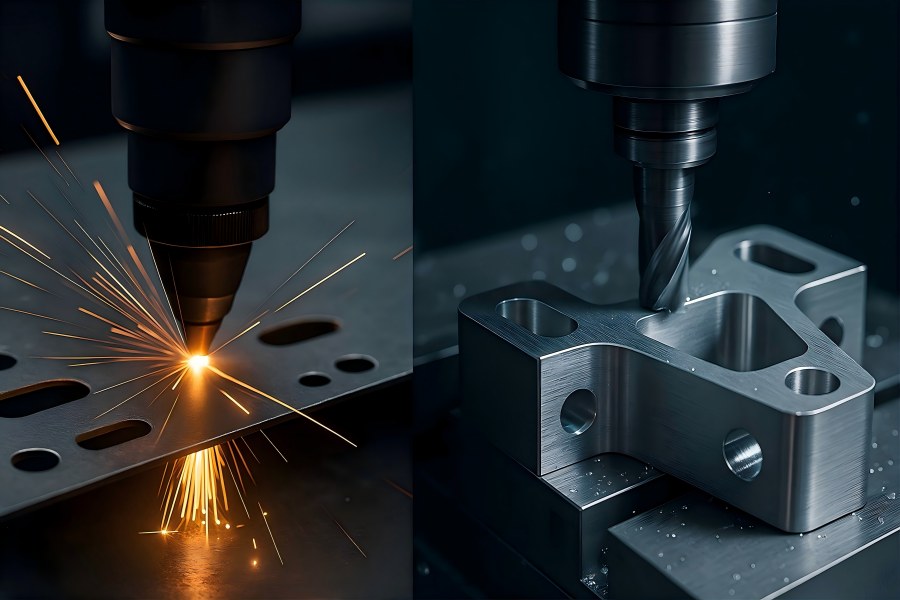

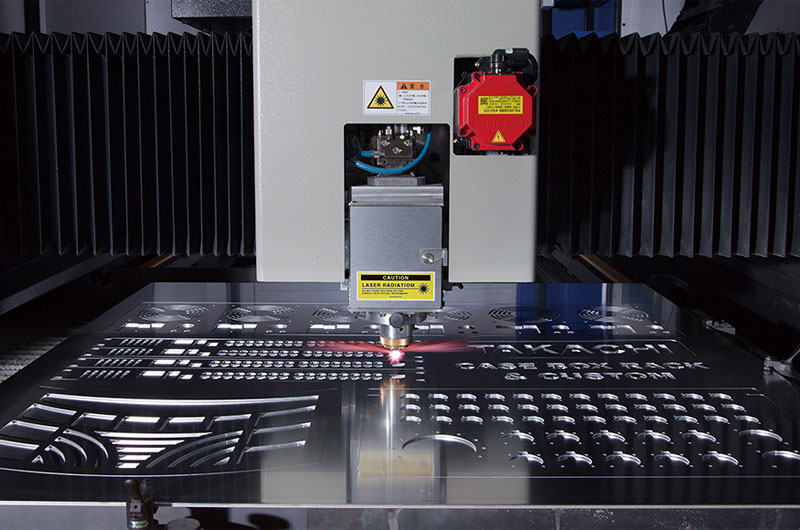

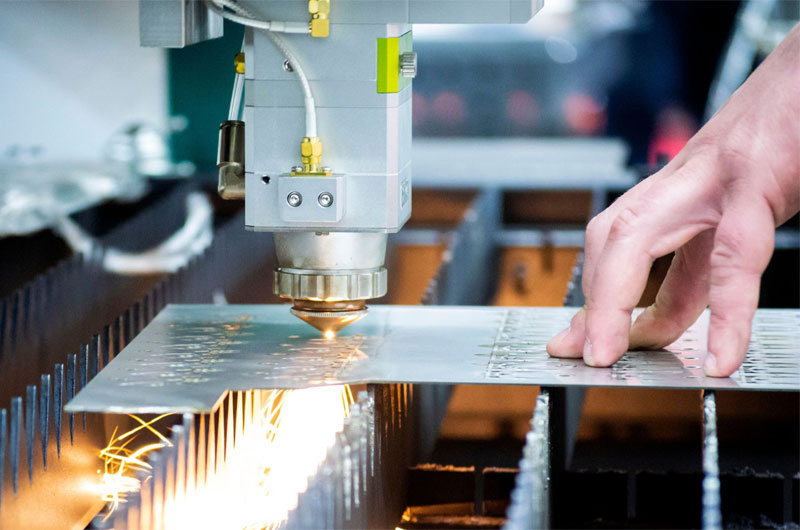

Sheet metal cutting is a critical process in modern manufacturing, spanning industries such as automotive, aerospace, HVAC, construction, and consumer […]

In the aerospace industry, where performance and safety are paramount, every component must meet the most stringent quality and dimensional […]

In today’s electronics-driven world, the demand for high-quality, durable, and precision-engineered electronic enclosures is higher than ever. Whether it’s for […]

When it comes to manufacturing and metal fabrication, selecting the right sheet metal cutting partner can make or break your […]

In the world of sheet metal cutting, efficiency is key, not only in terms of time and output, but also […]

In the metal fabrication industry, lead time is a crucial factor that directly impacts project schedules, costs, and customer satisfaction. […]

In the world of metal and sheet material processing, edge quality is a critical factor influencing the performance, appearance, and […]