Zinc plating is one of the most widely used metal-finishing methods across industries that depend on durable, corrosion-resistant steel components. Whether in automotive assemblies, aerospace fasteners, or consumer hardware, zinc coatings serve as a critical first line of defense against rust and oxidation.

However, not all zinc plating is made equally. Among the many classification types, Type I and Type II are two of the most commonly specified finishes under military and ASTM standards. Each offers distinct advantages in cost, appearance, and corrosion protection. When choosing the appropriate finish for your product’s performance and compliance needs, it is crucial to comprehend the distinctions.

Knowing the Fundamentals of Zinc Plating

A thin layer of zinc is applied to a steel or iron substrate via an electrochemical process called zinc plating. Zinc serves as a sacrificial coating, corroding first to shield the underlying metal from rust and damage.

Process steps typically include:

- Surface preparation: cleaning, degreasing, and pickling to remove oxides.

- Electroplating: immersion in a zinc salt solution with electric current applied.

- Rinsing and drying: removal of residues.

- Post-treatment: chromate conversion coating (Type I, II, etc.), sealants, or passivation for added corrosion resistance.

The resulting coating thickness generally ranges from 5 µm to 25 µm, depending on application and environment.

Zinc Plating Standards and Classifications

Zinc coatings are classified in numerous industrial and military specifications. Two of the most referenced are:

- ASTM B633 – Standard Specification for Electrodeposited Coatings of Zinc on Iron and Steel

- MIL-DTL-81706 / MIL-DTL-5541 (and older MIL-C-81706) covering chromate conversion for defense and aerospace applications

These specifications define both coating type and thickness class.

| ASTM Class | Coating Thickness (µm) | Recommended Use |

| Fe/Zn 5 | ~5 µm | Indoor, mild environments |

| Fe/Zn 8 | ~8 µm | Moderate humidity or light outdoor exposure |

| Fe/Zn 12 | ~12 µm | Outdoor, marine, or high-corrosion areas |

| Fe/Zn 25 | ~25 µm | Severe service, extended durability |

Each plating Type (I, II, III, IV) designates the chromate conversion finish applied after plating. This conversion layer largely determines appearance, corrosion life, and regulatory compliance.

Type I Zinc Plating — The Clear or Blue Finish

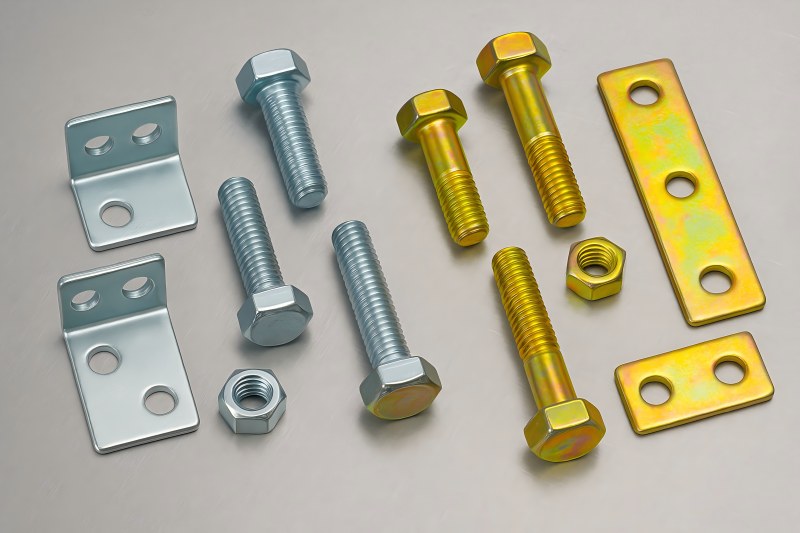

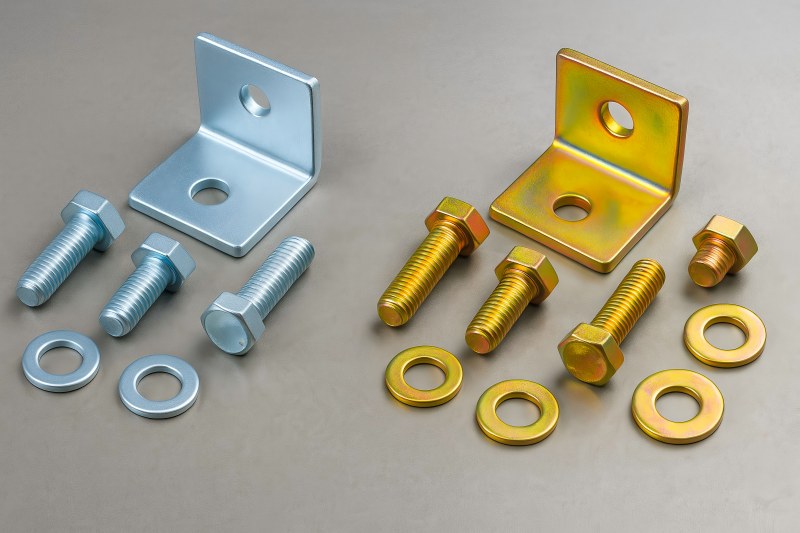

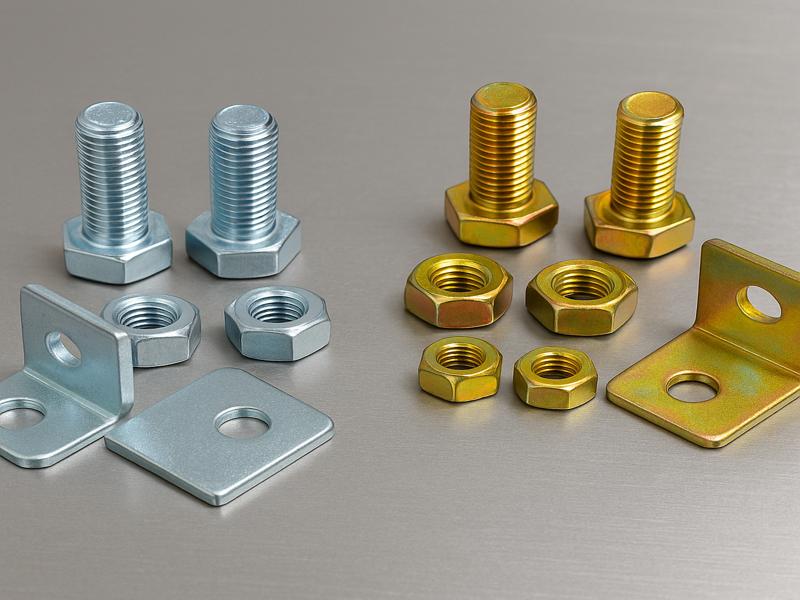

Type I zinc plating refers to zinc without chromate or with a clear/blue chromate passivation. The finish typically appears bright silver or bluish-silver. It offers an attractive aesthetic and is commonly chosen where visual appeal and indoor corrosion protection are priorities.

Key features of Type I:

- Bright, decorative appearance

- Moderate corrosion protection (typically 24–72 hours to white rust in ASTM B117 salt-spray tests)

- Excellent for indoor assemblies, appliances, or decorative fasteners

- Economical and environmentally friendly (often trivalent or no chromate)

| Feature | Type I Zinc Plating |

| Appearance | Bright silver or blue hue |

| Chromate Type | Clear or none |

| Corrosion Resistance | Moderate (24–72 hrs white rust) |

| Typical Use | Indoor, aesthetic parts |

| RoHS Compliance | Yes (trivalent or chromate-free) |

| Relative Cost | Lower |

Because it relies primarily on zinc’s sacrificial action rather than a thick chromate barrier, Type I coatings are best reserved for indoor, low-moisture environments.

Type II Zinc Plating — The Yellow Chromate Conversion

Type II zinc plating incorporates a yellow dichromate conversion coating, yielding a gold-to-iridescent appearance. The chromate film adds a secondary barrier that seals microscopic pores in the zinc and dramatically enhances corrosion performance.

Key features of Type II:

- Golden/yellow appearance (often iridescent)

- Superior corrosion resistance (120–200+ hours to white rust in salt-spray tests)

- Widely used in automotive, aerospace, and outdoor electrical hardware

- Optional sealers or topcoats can extend protection further

| Feature | Type II Zinc Plating |

| Appearance | Yellow or iridescent gold |

| Chromate Type | Yellow dichromate |

| Corrosion Resistance | High (120–200+ hrs white rust) |

| Typical Use | Outdoor or harsh environments |

| RoHS Compliance | Trivalent alternatives available |

| Relative Cost | Slightly higher |

Type II plating provides two to three times the corrosion life of Type I, making it the preferred choice for outdoor or high-humidity applications such as automotive under-hood components, marine fasteners, and structural brackets.

Key Differences Between Type I and Type II

| Comparison Factor | Type I | Type II |

| Chromate Layer | None / Clear | Yellow dichromate |

| Appearance | Silver / Blue | Yellow / Iridescent |

| Corrosion Protection | Moderate | High (2–3× longer life) |

| Ideal Use | Indoor, decorative | Outdoor, industrial |

| Environmental Compliance | Fully RoHS safe | Trivalent or sealed hex-free options |

| Cost | Lower | Slightly higher |

| Salt-Spray Hours (ASTM B117)* | 24–72 hrs to white rust | 120–200 hrs to white rust |

| Maintenance Interval | Shorter | Longer |

* Typical values; may vary depending on coating thickness and sealing process.

Environmental and Regulatory Considerations

Historically, yellow chromates contained hexavalent chromium (Cr⁶⁺), an effective but toxic compound now restricted under RoHS, REACH, and ELV directives.

Today, many finishers use trivalent chromium (Cr³⁺) systems that provide similar color and performance while being environmentally compliant.

Key regulations affecting zinc plating:

- RoHS (Restriction of Hazardous Substances): bans hexavalent chromium in consumer goods.

- REACH (EU): regulates the production and use of chemical substances.

- ELV (End-of-Life Vehicle): automotive directive limiting heavy-metal coatings.

Manufacturers now offer trivalent yellow chromate as a direct replacement for Type II (hexavalent), maintaining corrosion resistance up to 200 hours without white rust while remaining fully compliant.

Performance Testing and Durability

Performance is typically validated by ASTM B117 Salt-Spray Testing, which measures the hours to the first appearance of white rust (zinc corrosion products) and red rust (steel base corrosion).

| Plating Type | Salt-Spray Hours to White Rust | Salt-Spray Hours to Red Rust |

| Type I (Clear) | 24–72 hours | 96–144 hours |

| Type II (Yellow) | 120–200 hours | 200–400 hours |

| With Topcoat / Sealer | Up to 300 hours | 500+ hours |

Results vary by thickness class and sealer type, but the trend is consistent: Type II lasts significantly longer in corrosive or outdoor conditions.

Additional tests may include:

- Adhesion Tests (ASTM B571)

- Thickness Measurements (ASTM B499 or B504)

- Humidity Resistance Tests

How to Choose Between Type I and Type II

When selecting the right zinc finish, consider four core decision factors: environment, appearance, cost, and compliance.

| Condition | Recommended Type | Reasoning |

| Indoor, dry, aesthetic parts | Type I | Cost-effective, attractive finish |

| Outdoor or humid conditions | Type II | Higher corrosion resistance |

| Automotive under-hood | Type II | Meets OEM corrosion requirements |

| Consumer electronics | Type I | Bright, decorative finish |

| RoHS-critical components | Trivalent Type I or II | Environmentally compliant |

| Marine / industrial | Type II with sealer | Maximum protection |

Example Scenario 1: An electronics manufacturer producing indoor control panels selects Type I clear zinc for its bright finish and low cost.

Example Scenario 2: A heavy-equipment OEM chooses Type II yellow zinc with trivalent chromate to ensure outdoor longevity while maintaining compliance.

Ultimately, Type I suits controlled environments where visual aesthetics are important, while Type II is ideal for components exposed to weather, moisture, or salt air.

Alternatives to Zinc Plating

In some high-performance or specialized applications, other coatings may outperform basic zinc plating.

| Alternative Coating | Description | Typical Benefit |

| Zinc-Nickel (5–15 % Ni) | Alloy plating offers superior corrosion resistance | 5–10× life vs zinc alone |

| Zinc-Iron Alloy | Enhanced wear and paint adhesion | Excellent for automotive |

| Hot-Dip Galvanizing | A thick zinc layer is applied by dipping | Very high durability for structural steel |

| Electroless Nickel | Non-electrolytic nickel phosphorus layer | Exceptional hardness and uniformity |

| Organic or Powder Coating Topcoats | Polymer barrier on top of zinc | Added UV and chemical protection |

While these methods cost more, they provide extended life or specialized functional properties (lubricity, conductivity, wear resistance).

The Future of Zinc Plating

Advances in surface chemistry, automation, and environmental control are transforming the zinc-plating industry.

- Trivalent chromates are replacing legacy hexavalent finishes at scale.

- Nanoceramic sealers and self-healing coatings extend service life beyond 500 hours of salt-spray exposure.

- Automated rack and barrel plating lines now deliver precise thickness control and traceability for OEM supply chains.

These innovations make zinc plating more sustainable, consistent, and adaptable to modern industrial requirements.

Conclusion: Balancing Performance, Cost, and Compliance

Selecting between Type I and Type II zinc plating is about finding the right balance among performance, environment, and regulatory goals.

- Choose Type I when cost, brightness, and indoor corrosion protection are priorities.

- Choose Type II when your parts face humidity, salt, or outdoor exposure — or when extended service life outweighs small cost differences.

As regulations tighten and customer expectations rise, partnering with an experienced finishing provider ensures both technical compliance and optimized performance. When properly specified and applied, zinc plating—whether clear or yellow—continues to offer one of the most economical and reliable methods of corrosion protection in modern manufacturing.