Global manufacturers increasingly prioritize sourcing sheet metal components to cut costs and secure reliable, scalable production. China, Vietnam, and India have become Asia’s top sourcing hubs, each offering distinct advantages in labor, capabilities, materials, and engineering support. This article compares these three regions to help buyers choose the best option based on cost, quality, delivery, and operational needs.

Why Companies Outsource Sheet Metal Fabrication

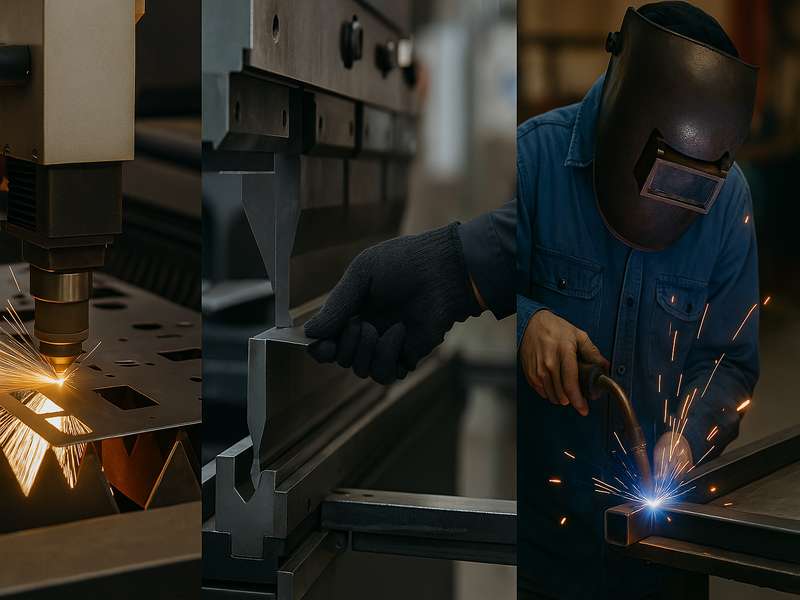

Sheet metal fabrication—including laser cutting, CNC bending, stamping, machining, welding, tapping, and surface finishing—requires specialized equipment and skilled labor. Outsourcing to manufacturing hubs offers several business advantages:

Cost Efficiency

Asian markets provide significantly lower labor and production overhead costs compared to the US or EU, enabling competitive pricing for high-volume sheet metal parts.

Advanced Manufacturing Capabilities

From laser cutting machines to robotic welding systems, suppliers in Asia offer advanced equipment investments that many OEMs prefer not to install themselves.

Access to Complete Industrial Ecosystems

Strong supply chains for raw materials, fasteners, hardware, and surface treatment services help reduce lead times.

Scalability

Asian suppliers handle mass production efficiently, especially for housing frames, enclosures, racks, modular assemblies, and custom-fabricated components.

Engineering & DFM Support

Specialized factories provide design-for-manufacturing (DFM) guidance, assembly optimization, fixture development, and precision fabrication help.

Key Factors to Evaluate When Sourcing Sheet Metal Parts

Before selecting a country, buyers must evaluate critical sourcing factors:

- Material standards (SS304, SS316, SPCC, aluminum 5052/6061, GI steel, copper, etc.)

- Precision capabilities (±0.1 mm to ±0.02 mm tolerance)

- Labor skill levels

- Automation investment (robotic welding, fiber lasers)

- Engineering communication and project management

- Export experience, certifications, and industry references

- Lead time consistency

- Logistics and shipping time to target markets

These factors can significantly affect total cost, production consistency, and long-term supplier reliability.

China: Advanced, High-Capacity, Export-Oriented Manufacturing

China remains the global leader in sheet metal fabrication due to its mature supply chain and engineering-driven production environment.

Strengths

- The most advanced equipment ecosystem in Asia

- Consistent production quality with tight tolerances

- Strong automation adoption in welding, bending, and assembly

- Complete material market for steel, stainless steel, and aluminum

- Large production capacity for high-volume orders

Ideal for:

High-precision parts, complex assemblies, mass production, rapid development cycles, and projects requiring detailed engineering.

Challenges

- Labor costs have increased gradually

- Tariff exposure in certain markets

- Higher MOQs in many factories

Vietnam: Competitive Cost & Growing Manufacturing Base

Vietnam has become a preferred sourcing market for companies seeking a balance between cost and quality, especially after global supply diversification trends.

Strengths

- Lower labor costs than in China

- Strong government support for manufacturing investments

- Good for consumer electronics housings, brackets, and enclosures

- Short shipping routes to the US and Europe

- Foreign-invested factories bring international standards

Ideal for:

Light–medium complexity components, mid-volume production, and projects needing lower labor cost but acceptable quality consistency.

Challenges

- Smaller supplier ecosystem

- Materials are sometimes imported from China

- High-end precision capabilities are still developing

India: High Cost Savings for Large or Low-Complexity Metal Work

India is emerging as a cost-effective destination for sheet metal fabrication, especially for heavier gauge metals and large assemblies.

Strengths

- Very low labor cost

- Good for welded structures, frames, chassis, agricultural and industrial machinery components

- Strong base of mechanical engineering talent

- Large-scale manufacturing clusters in Pune, Chennai, Noida, and Gujarat

Ideal for:

Heavy-gauge parts, large weldments, low- to medium-precision assemblies.

Challenges

- Quality consistency varies widely

- Longer production cycles

- Less mature export logistics

- Fewer high-automation factories compared to China

Cost Comparison Table

Below is a generalized comparison for typical sheet metal components (laser cut + bending + welding + powder coating), assuming mid-size production quantities.

| Category | China | Vietnam | India |

| Labor Cost | Medium | Low | Very Low |

| Part Price (Relative) | ★★★ (medium-high) | ★★☆ (medium-low) | ★★ (low) |

| Tooling Cost | Moderate | Low–Moderate | Low |

| Material Cost | Lowest (domestic supply) | Often imported | Moderate |

| Overall Cost Score | 7/10 | 8/10 | 9/10 |

Quality & Engineering Comparison

Quality levels vary significantly between countries. China leads in precision and consistency, while Vietnam offers stable quality for mid-range products. India is improving but still inconsistent at high complexity.

| Quality Factor | China | Vietnam | India |

| Precision Tolerance | ±0.02–0.10 mm | ±0.05–0.15 mm | ±0.10–0.30 mm |

| Welding Quality | Excellent | Good | Good–Moderate |

| Surface Finish | Excellent | Good | Moderate |

| Automation Level | Very High | Medium | Low–Medium |

| Engineering Support | Strong | Moderate | Moderate–Low |

| Quality Score | 9/10 | 7/10 | 6/10 |

Lead Time & Logistics Comparison

Lead time plays a key role for brands needing fast replenishment.

| Parameter | China | Vietnam | India |

| Sample Lead Time | 5–10 days | 7–14 days | 10–20 days |

| Mass Production | 15–25 days | 20–30 days | 25–40 days |

| Port Efficiency | Excellent | Very Good | Good |

| Shipping Time to the US West | 15–18 days | 20–24 days | 22–28 days |

| Overall Lead Time Score | 9/10 | 7/10 | 6/10 |

Capabilities & Industrial Strength Comparison

Different countries specialize in different areas of sheet metal fabrication.

| Capabilities | China | Vietnam | India |

| Laser Cutting | ★★★★★ | ★★★★ | ★★★ |

| CNC Bending | ★★★★★ | ★★★★ | ★★★ |

| Robotic Welding | ★★★★★ | ★★★ | ★★☆ |

| Precision Stamping | ★★★★★ | ★★★★ | ★★★ |

| Assembly & Box Build | ★★★★★ | ★★★ | ★★★ |

| Surface Finishing | ★★★★★ | ★★★★ | ★★★ |

| Overall Capability Score | 9.5/10 | 7.5/10 | 6.5/10 |

Risks & Challenges

China

- Rising labor rates

- Exposure to geopolitical tensions and tariffs

- Higher MOQs for some factories

Vietnam

- Small supplier base limits capacity scaling

- Imported materials increase cost volatility

- Inconsistent precision in complex assemblies

India

- Large quality gaps between factories

- Incomplete supply chains cause delays

- Less efficient logistics for global shipments

Which Country Should You Choose?

Your choice depends on your business priorities:

Choose China If You Need:

- Highest precision

- Fastest production speed

- Complex fabrication or assembled products

- Strong engineering and DFM support

- Mature quality systems

Choose Vietnam If You Need:

- Balanced cost and quality

- Consumer electronics, enclosures, brackets

- Medium-complexity sheet metal parts

- Lower labor costs while maintaining export standards

Choose India If You Need:

- Heavy-gauge sheet metal fabrications

- Large structural components

- Lowest-cost sourcing for non-precision parts

- Budget-sensitive projects

How to Select the Right Supplier (Checklist)

Regardless of region, buyers should evaluate suppliers using these criteria:

Factory Capability Assessment

- Laser wattage, CNC bending length, and welding test samples

- Robotic welding and automated systems

- Surface treatment partners

Quality Assurance Level

- ISO certifications

- CMM, 3D scanners, micro-height testers

- Weld penetration and strength testing

Engineering and Communication

- DFM support

- Fixture and jig development

- Clear documentation and drawing feedback

Pilot Production

- Produce samples and pre-production batches

- Check tolerance stability and defect rate

Logistics & Packaging

- Export carton standards

- Anti-rust packaging for long-sea shipments

- Ability to meet the delivery schedule

China, Vietnam, and India each play an important role in the global sheet metal supply chain. China remains the leader in precision, automation, and mass production. Vietnam offers a solid balance between cost and quality, especially for electronics and consumer goods. India provides the most significant labor cost advantage and strong capabilities in heavy fabrications.

Choosing the right sourcing region depends on your product complexity, tolerance requirements, budget level, and target market. By evaluating capabilities, quality systems, lead times, and total cost structure, companies can build a reliable and cost-effective sheet metal supply chain across Asia.