Hole cutting is a fundamental process in sheet metal fabrication, used in a wide variety of industries to create precise openings in metal sheets.

This process can be used for applications ranging from creating ventilation holes in appliances to making holes for fasteners in structural components.

Depending on the material, thickness, and design specifications, several methods can be used to cut holes in metal sheets, each with its advantages and limitations.

This article explores common techniques, applications, and best practices for hole cutting in metal sheets.

Common Hole Cutting Techniques for Metal Sheets

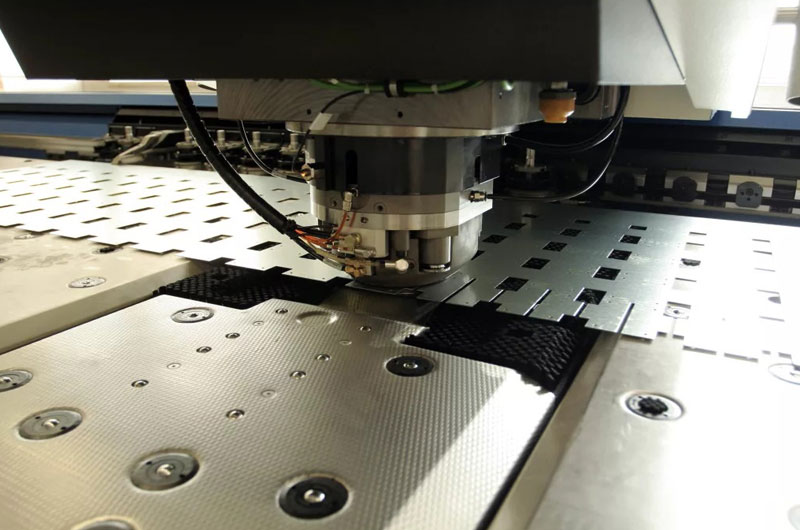

Laser Cutting

Laser cutting is an exacting technique that utilizes a concentrated laser beam to melt or vaporize the material, producing clean, smooth-edged holes in metal sheets. It’s perfect for tasks requiring precision and complex designs, such as aerospace components, electronics casings, and medical equipment.

Advantages:

- Precision and accuracy in cutting.

- Minimal heat-affected zone, reducing material distortion.

- Capable of cutting very thin to thick materials.

Limitations:

Higher energy consumption compared to other methods.

Limited to metals that can be easily vaporized or melted (e.g., mild steel, aluminum, stainless steel).

Plasma Cutting

Plasma cutting employs a high-temperature plasma arc to melt metal and blow away the molten material, making it an efficient and rapid method for cutting thicker materials. It is used for large-scale hole cutting in construction, automotive manufacturing, and shipbuilding.

Advantages:

- Efficient for cutting thick sheets (up to several inches thick).

- High cutting speed and flexibility.

- Suitable for ferrous and non-ferrous metals.

Limitations:

- Edges may require additional finishing, as plasma cutting can produce rougher cuts.

- Less precision compared to laser cutting.

Waterjet Cutting

Waterjet cutting uses a high-pressure stream of water (often mixed with abrasives) to erode the metal and create holes. It is used when a material needs to be cut without introducing heat, such as in the food industry, aerospace, or materials that can be sensitive to heat.

Advantages:

- No heat-affected zone, preventing distortion or warping.

- Can cut a wide range of materials, from metals to composites and ceramics.

- Extremely precise and capable of cutting complex shapes.

Limitations:

- Slower than laser or plasma cutting.

- Requires more complex setup and maintenance.

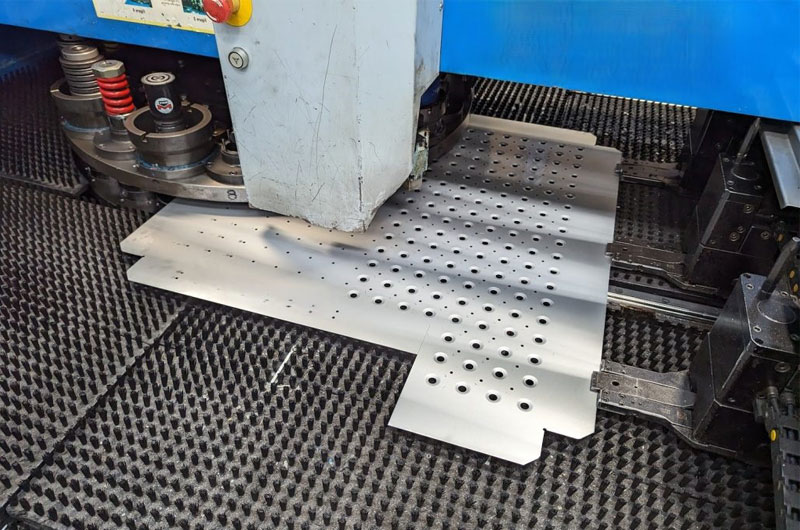

Punching

Punching uses a die and punch to shear the metal, forcing the material through the die to create a hole. This is one of the oldest and most common methods for hole cutting in sheet metal. Metal punching is ideal for mass production of uniform holes, such as those found in automotive body panels, HVAC components, and electrical enclosures.

Advantages:

- Fast and cost-effective for high-volume production.

- Suitable for making consistent, round holes.

- Capable of punching multiple holes at once.

Limitations:

- Limited to relatively simple hole shapes.

- Punching may cause material distortion, especially with thicker metals.

Drilling

Drilling involves using a rotating drill bit to remove material and create a hole. While drilling is often associated with thicker materials, it can also be used for sheet metal, particularly when precise, small holes are required. It is ideal for precise holes that require threading, such as bolt holes in machinery or parts that need to be fastened.

Advantages:

- Precision in small-hole creation.

- Suitable for holes that require internal threading.

- Can be used on a wide variety of materials.

Limitations:

- Not suitable for mass production of large holes.

- Requires specialized tools and slower speeds than other cutting methods.

Stamping

Stamping involves pressing a die onto sheet metal to create holes and other shapes in one press cycle. This method is commonly used for high-volume production. Common in the automotive, appliance, and electronics industries, metal stamping is used to create uniform holes for assembly.

Advantages:

- Very cost-effective for large production runs.

- High precision and consistency.

Limitations:

- High initial tooling costs for creating custom dies.

- Limited to specific hole shapes and sizes.

Considerations for Choosing a Hole Cutting Method

Material Type

The type of metal being cut plays a major role in the choice of cutting method. Softer materials like aluminum are easier to cut with laser or waterjet cutting, while thicker metals like steel may require plasma cutting or punching.

Hole Size and Shape

The size and shape of the hole are also important considerations. Laser cutting and waterjet cutting can produce intricate, non-circular shapes, while punching and drilling are ideal for round holes. For mass production of round holes, punching may be the most cost-effective option.

Thickness of Metal

Thicker metals may be more suited for plasma cutting or punching, as these methods are designed to handle the high energy required to cut through heavy materials. For thinner sheets, laser or waterjet cutting is ideal due to their precision.

Volume of Production

For low-volume or one-off projects, methods like waterjet cutting or laser cutting may be more appropriate. However, for large-scale production, punching or stamping may be the most efficient and cost-effective options.

Tolerances and Finishes

Different cutting methods yield varying levels of precision and edge finishes. Laser and waterjet cutting provide clean, precise edges with minimal finishing required. Punching and plasma cutting, on the other hand, may require additional edge cleaning.

Best Practices for Hole Cutting in Metal Sheets

- Pre-Program Design: Before starting any hole cutting operation, ensure that the design is optimized for the cutting method chosen. For example, designing holes with proper spacing and alignment can improve efficiency and reduce waste.

- Use High-Quality Tools: Whether using a punch, drill, or laser, high-quality tools and machines will ensure better precision and longer tool life.

- Consider Material Properties: Take into account the material’s hardness, thickness, and thermal conductivity when choosing the cutting method. For example, stainless steel may require slower speeds during laser cutting to avoid excessive heat buildup.

- Optimize Cutting Parameters: Adjust cutting speeds, feed rates, and other machine settings to suit the specific material and thickness being worked with to achieve the best results.

- Clean Edges and Post-Processing: Depending on the method used, some holes may require post-processing to remove burrs or smooth the edges for aesthetic or functional reasons.

Conclusion

Hole cutting for metal sheets is an essential process in metal fabrication, with various techniques available to suit different materials, hole sizes, and production requirements.

By understanding the specific requirements of your project, such as material type, hole shape, production volume, and budget, you can select the best cutting technique for your needs.