Estimating welding costs accurately is essential for project planning, budgeting, and profitability.

Whether you are a fabricator, project manager, or engineer, understanding the factors that influence welding expenses can help you develop reliable cost estimates and avoid financial surprises.

This article explores the key elements involved in estimating welding costs for custom projects, breaking them down into direct and indirect cost categories and providing a systematic approach for accurate estimation.

Understanding Welding Cost Components

Accurately estimating welding costs begins with understanding the key factors that make up the total expense. These include:

1. Labor Costs

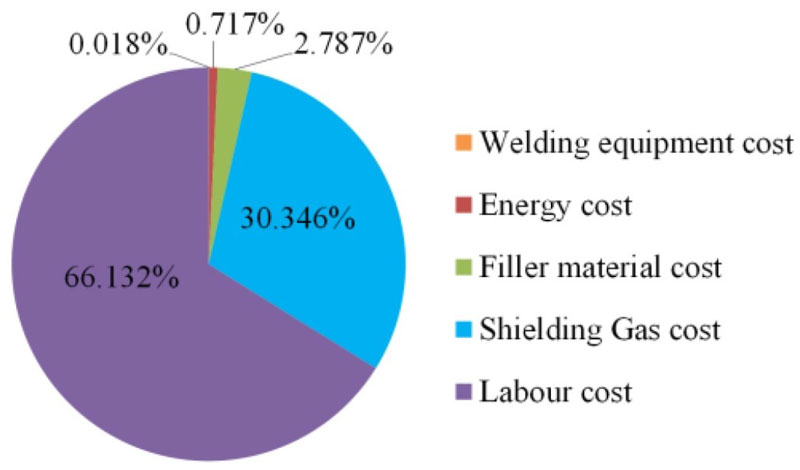

Labor is one of the most significant components of welding expenses. It is calculated based on:

- Hourly wage or rate of the welder

- Time required to complete the welds

- Skill level needed (e.g., TIG welding often requires more skill and time than MIG welding)

For example, a certified welder performing precision TIG welding may cost more per hour but produce higher-quality welds that require less rework.

2. Material Costs

Welding materials include:

- Base metals (steel, aluminum, stainless steel, etc.)

- Filler metals (rods, wires, electrodes)

- Shielding gases (argon, CO₂, helium, or mixes)

- Consumables (nozzles, tips, grinding wheels)

Accurate estimates require knowing the weight and type of materials and calculating their costs per unit or per pound.

3. Equipment Costs

This includes:

- Depreciation or rental fees for welding equipment

- Maintenance and repair costs

- Power consumption (especially for high-energy processes like arc welding)

Though often overlooked, equipment overhead can significantly impact total cost for large or long-term projects.

4. Overhead and Indirect Costs

Overhead includes:

- Shop utilities

- Facility rent

- Administrative costs

- Safety gear and PPE

Allocate a portion of these expenses to the project based on time or labor hours.

5. Preparation and Finishing Costs

These are essential for metal welding fabrication and may include:

- Cutting and edge preparation

- Fixturing and positioning

- Cleaning and surface treatment

- Inspection, testing, and post-weld treatments

Even though they don’t involve actual welding, these tasks consume significant time and resources.

Step-by-Step Welding Cost Estimation

Here’s how you can create a structured approach to estimating welding costs:

Step 1: Define the Scope of Work

Clearly define:

- The type and volume of welds

- The geometry and accessibility of weld joints

- Welding positions and any special requirements (e.g., overhead welding, pressure vessel standards)

This helps determine the process, labor effort, and quality controls required.

Step 2: Select the Welding Process

Choose a welding process based on the material, design, and performance requirements:

- MIG (GMAW): Suitable for high-speed production

- TIG (GTAW): Best for precision or thin materials

- Stick (SMAW): Ideal for outdoor or structural work

- Flux-Cored (FCAW): Good for thick materials and heavy-duty applications

Each process varies in terms of equipment, speed, material consumption, and labor.

Step 3: Calculate Labor Time and Cost

Estimate how long each weld will take. Factors to consider:

- Joint length and type

- Travel speed (inches per minute)

- Number of passes

- Welder’s efficiency

Formula Example:

Labor cost = (Weld length ÷ travel speed) × (1 ÷ efficiency rate) × hourly labor rate

If a weld is 60 inches long, the welder travels at 10 inches/min, and efficiency is 70%:

- Time = 60 / 10 = 6 minutes

- Adjusted time = 6 / 0.7 ≈ 8.6 minutes

- Labor cost at $50/hour = (8.6 / 60) × 50 ≈ $7.17

Repeat this for all joints in the project.

Step 4: Estimate Material Costs

Include:

- Filler metal consumption based on weight per inch of weld

- Shielding gas usage, typically measured in cubic feet per hour (CFH)

- Base metal cost per sheet or per pound

- Consumables per weld or per hour of operation

Use vendor quotes or historical data to price each item accurately.

Step 5: Add Equipment and Power Costs

Equipment costs can be:

- Amortized daily/hourly cost of the machine

- Electricity usage (kWh) × rate per kWh

For example:

- Machine uses 5 kWh per hour

- Rate is $0.10 per kWh

- Power cost per hour = 5 × $0.10 = $0.50

Include rental or replacement costs if applicable.

Step 6: Factor in Preparation and Post-Weld Work

Preparation tasks like cutting, grinding, and fixturing can be time-intensive. Similarly, post-weld cleaning, visual or NDT inspection, and rework should be budgeted.

If these tasks are subcontracted, include those quotes. If done in-house, apply similar labor and material costing as for welding.

Step 7: Add Overhead and Profit Margin

Overhead is typically added as a percentage of labor and material costs, e.g., 10–30%. Finally, apply your desired profit margin (e.g., 15–25%) to the subtotal to determine the final price for the customer.

Tools and Software for Welding Cost Estimation

To improve accuracy and efficiency, consider using welding cost calculators or manufacturing ERP software that offers built-in modules for job costing. Popular tools include:

- WeldCostCalc

- WeldShop Calculator

- FabSuite

- SolidWorks Costing Module

These tools help automate calculations and reduce errors in manual estimates.

Practical Tips for Accurate Estimation

- Use real-world data: Reference past projects with similar materials and designs.

- Consult with welders: Experienced professionals can identify inefficiencies or time-saving techniques.

- Consider tolerance and quality standards: Projects requiring X-ray inspection or special certifications will be more costly.

- Plan for contingencies: Include a buffer (5–10%) for unexpected delays or rework.