Machining hard-to-machine metals is one of the more challenging tasks in the manufacturing industry. These metals, often referred to as difficult-to-machine (DTM) materials, can cause issues such as tool wear, heat buildup, material distortion, and excessive cutting forces.

Metals like titanium, high-strength alloys, stainless steels, and superalloys are all classified as hard-to-machine due to their toughness, hardness, and other characteristics that resist deformation during cutting.

To improve the workability of these metals, manufacturers must use specific techniques and strategies that reduce friction, heat, and wear during the machining process.

This article explores the various methods, tools, and processes that can enhance the workability of hard-to-machine metals, improving efficiency, tool life, and part quality.

1. Understanding Hard-to-Machine Metals

Before diving into strategies for improving workability, it is essential to understand why certain metals are hard to machine. These materials have a combination of high hardness, tensile strength, toughness, and low thermal conductivity. Some of the most common examples of hard-to-machine metals include:

- Titanium Alloys: Known for their strength-to-weight ratio and resistance to corrosion, titanium alloys are widely used in aerospace and medical applications. However, their low thermal conductivity and high hardness make them difficult to machine.

- Stainless Steels: Stainless steels, especially high-alloy variants such as 17-4 PH and 15-5 PH, have high hardness and strength. These characteristics contribute to challenges in cutting, as they generate heat quickly, which can degrade tools.

- Superalloys: Metals like Inconel and Hastelloy are used in extreme conditions like high temperatures. These alloys offer high strength at elevated temperatures but are highly resistant to machining.

- Tool Steels: Tool steels, often used in manufacturing tools, dies, and molds, are tough and resistant to wear but are difficult to machine due to their hardness.

2. Optimizing Cutting Parameters

One of the most straightforward ways to improve the workability of hard-to-machine metals is by optimizing cutting parameters. These parameters have a direct effect on metal cutting forces, tool lifespan, and the generation of heat during machining.

Key parameters to adjust include:

Cutting Speed

Cutting speed refers to how fast the cutting tool moves through the material. For hard-to-machine metals, reducing cutting speed is often necessary. Lower speeds help prevent overheating of both the tool and the workpiece. The ideal cutting speed depends on the material being processed; generally, lowering the cutting speed helps reduce the risk of thermal damage and tool wear.

Feed Rate

Feed rate refers to the speed at which the tool progresses into the material. Higher feed rates can increase cutting forces, leading to higher tool wear and material deformation. For hard-to-machine metals, a lower feed rate is typically preferred, which helps to reduce the load on the tool and improve finish quality.

Depth of Cut

The depth of cut indicates the thickness of material removed in a single pass. For hard-to-machine metals, a shallow depth of cut is generally more effective, as it reduces the cutting forces and minimizes heat buildup. However, this should be balanced with the need for productivity, as excessively shallow cuts may slow down production rates.

3. Using the Right Cutting Tools

Choosing the appropriate cutting tools is critical when working with hard-to-machine metals. Cutting tools must be made from materials that can endure high temperatures and resist wear during the machining process.

Coated Cutting Tools

Tool coatings like Titanium Nitride (TiN), Titanium Carbonitride (TiCN), and Diamond-like Carbon (DLC) can significantly improve tool performance when machining hard metals by reducing friction, minimizing heat buildup, and extending tool life. They also help in minimizing the adhesion of material to the cutting edge, which can lead to premature tool failure.

Carbide Tools

Carbide, especially cemented carbide, is one of the most commonly used materials for cutting tools when machining hard-to-machine metals. Carbide tools offer exceptional hardness, wear resistance, and durability, making them ideal for demanding machining tasks and applications. In cases where carbide tools may not be enough, using ceramic tools or polycrystalline diamond (PCD) tools may be an option.

Tool Geometry

The cutting tool’s geometry design also plays a crucial role in performance. Tools with sharper cutting edges reduce cutting forces and improve surface finish. Using tools with specific geometries, such as positive rake angles, can help reduce the cutting forces and allow for better chip evacuation.

4. Applying Coolants and Lubricants

Proper use of coolants and lubricants can significantly improve the machinability of difficult-to-machine metals. These substances help reduce the temperature at the cutting interface, preventing thermal damage to both the tool and the workpiece.

High-Pressure Coolants

Coolants applied at high pressures can help dissipate heat effectively and ensure better chip removal. In the case of hard metals, it is important to use coolants that can withstand high temperatures without breaking down. Water-soluble oils and synthetic coolants are typically used for high-performance cutting processes.

Minimum Quantity Lubrication (MQL)

In situations where the use of traditional coolant is impractical or undesirable, minimum quantity lubrication (MQL) can be a viable alternative. Minimum Quantity Lubrication (MQL) involves applying a fine mist of lubricant directly to the cutting zone, reducing friction, minimizing heat, and improving both tool longevity and surface finish.

5. Advanced Machining Techniques

Several advanced machining techniques are specifically designed to improve the efficiency of working with hard-to-machine metals.

Cryogenic Machining

Cryogenic machining uses liquid nitrogen or other cryogenic gases to cool both the cutting tool and the workpiece. This technique helps reduce the temperature at the cutting interface, preventing thermal damage and improving tool life. It is particularly effective when machining materials that generate high heat, such as titanium and superalloys.

Electrical Discharge Machining (EDM)

EDM is a non-traditional machining method that uses electrical discharges to remove material from the workpiece. It is often used for hard metals that are difficult to machine using conventional methods. EDM machining is ideal for intricate shapes and delicate features, as it doesn’t apply direct mechanical forces to the material.

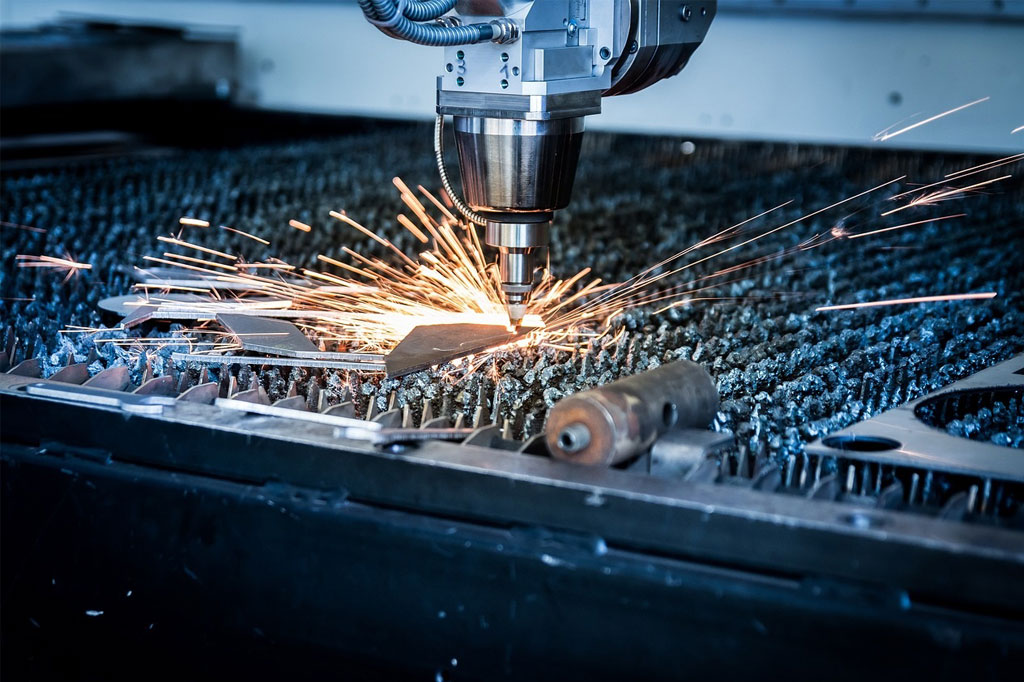

Laser Machining

Laser machining uses high-energy laser beams to melt or vaporize material from the workpiece. This technique is particularly effective for cutting tough materials like titanium and high-alloy steels. Laser machining offers high precision, minimal heat-affected zones, and the ability to work with complex shapes.

6. Optimizing Workpiece Setup

The setup of the workpiece can also impact the efficiency of machining. For hard-to-machine metals, it is crucial to ensure that the workpiece is securely held in place to prevent any unwanted movement during machining. Using advanced clamping systems, such as vacuum fixtures or magnetic workholding, can help improve accuracy and reduce setup time.

Additionally, proper alignment and balanced workpiece positioning can help reduce cutting forces and vibrations, resulting in a smoother machining process and higher-quality finishes.