Different cutting technologies, such as laser cutting, plasma cutting, waterjet cutting, and mechanical cutting, have specific limitations and advantages when it comes to handling material thickness.

This article explores these limits and provides a comparative overview to help manufacturers and engineers choose the most appropriate cutting process for their applications.

1. Laser Cutting

Laser cutting uses a focused beam of light to melt or vaporize materials, offering exceptional precision and speed. It’s suitable for both metals and non-metals such as plastics, wood, and ceramics.

Material Thickness Limits:

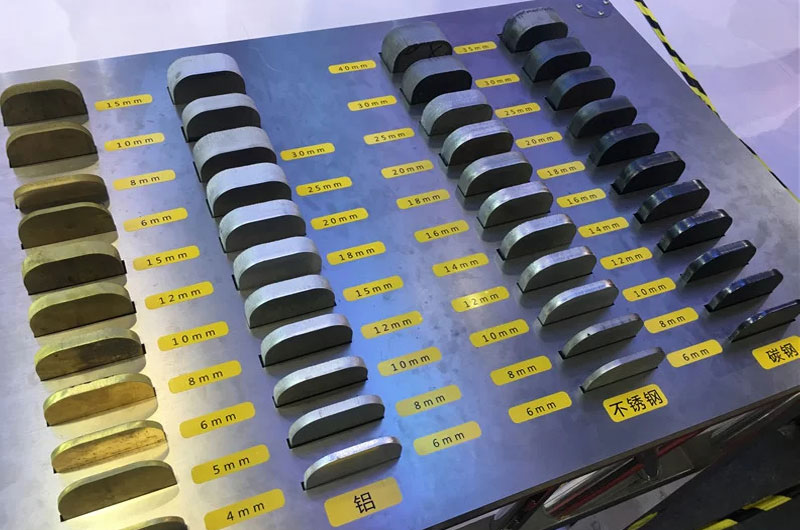

- Carbon Steel: Up to 25 mm (with CO₂ lasers), 30 mm (with fiber lasers)

- Stainless Steel: Up to 20–25 mm

- Aluminum: Up to 15–20 mm

- Plastics/Wood: Varies; typically up to 20–25 mm depending on material type and density

Notes:

- Laser cutting excels at thin-to-medium thickness materials, particularly below 10 mm, where it provides clean edges and tight tolerances.

- Thickness capacity decreases with reflectivity and thermal conductivity (e.g., copper or brass can be more difficult).

- Assist gases (oxygen, nitrogen) help optimize cutting for specific materials and thicknesses.

2. Plasma Cutting

Plasma cutting uses an ionized gas jet to melt and remove material. It is commonly used for cutting conductive metals.

Material Thickness Limits:

- Mild Steel: Up to 50 mm (handheld systems), 150 mm (with special systems)

- Stainless Steel: Up to 38 mm

- Aluminum: Up to 38 mm

Notes:

- Plasma cutting is highly effective for thicker metal plates, particularly from 6 mm to 50 mm.

- Offers higher speed than oxy-fuel for mid-range thicknesses.

- Not suitable for non-conductive materials like plastics or glass.

3. Waterjet Cutting

Waterjet cutting employs a powerful stream of high-pressure water, often combined with abrasive substances such as garnet, to precisely erode and slice through the material.

Material Thickness Limits:

- Metals (Steel, Aluminum, Titanium): Up to 150 mm or more

- Stone/Ceramics: Up to 200 mm

- Glass, Plastics, Composites: Up to 100–150 mm

Notes:

- Waterjet is the most versatile in terms of materials and thickness.

- It’s ideal for materials sensitive to heat, as it is a cold-cutting process.

- Capable of cutting very thick materials, but the cutting speed and precision decrease as the thickness increases.

4. Oxy-Fuel Cutting (Flame Cutting)

Oxy-fuel cutting involves a chemical reaction between oxygen and the base metal (typically steel), burning the metal and removing the molten slag with the oxygen jet.

Material Thickness Limits:

- Mild Steel: Typically 5 mm to 300 mm

- Cast Iron/Stainless/Aluminum: Not suitable

Notes:

- Best suited for thick carbon steel—above 25 mm.

- Very cost-effective for heavy-duty cutting where precision is not a top priority.

- Cannot cut non-ferrous or stainless steels due to lack of oxidizing reaction.

5. Mechanical Cutting (Shearing, Sawing, Milling)

Mechanical cutting includes a wide range of tools like saws, mills, and shears that remove material through physical force and friction.

Material Thickness Limits:

- Sheet Metal (Shearing): Up to 25 mm depending on machine capacity

- Sawing (Band Saw or Circular Saw): Up to 300–500 mm or more, depending on blade and material

- Milling (for surface profiling): Effective for 1–50 mm cuts at a time, depending on pass depth

Notes:

- Mechanical cutting is versatile and widely used for both thin sheets and thick blocks.

- Shearing is fast but limited to straight-line cuts and thinner materials.

- Milling and sawing allow complex shapes and thick material removal but are slower and more tool-wear intensive.

Summary Comparison Table

| Cutting Method | Typical Max Thickness | Suitable Materials | Precision | Speed |

|---|---|---|---|---|

| Laser Cutting | 30 mm (Steel) | Metals, Plastics, Wood | Very High | High |

| Plasma Cutting | 150 mm (Steel) | Conductive Metals | Medium-High | Very High |

| Waterjet Cutting | 150–200 mm | All Materials | High | Medium |

| Oxy-Fuel Cutting | 300 mm (Carbon Steel) | Carbon/Mild Steel Only | Low-Medium | Medium |

| Mechanical Cutting | 500 mm+ (Sawing) | Metals, Plastics, Wood, Composites | Medium-High | Low-Medium |

Key Factors Influencing Thickness Limits

When selecting a cutting technology, thickness limits are just one piece of the puzzle. Several other factors influence which method is best:

- Material Type and Properties

- Thermal conductivity, reflectivity, and hardness affect cutting efficiency.

- For example, copper’s high reflectivity limits laser cutting depth.

- Edge Quality Requirements

- Laser and waterjet produce superior edge finishes compared to plasma or flame cutting.

- Tolerance and Precision Needs

- Laser and waterjet cutting are ideal for applications demanding tight tolerances.

- Heat Sensitivity

- Waterjet is preferred for materials that warp or degrade with heat (e.g., composites, plastics).

- Cutting Speed vs. Cost Trade-Off

- Plasma is fast and affordable for medium-thick metal; laser offers precision but at a higher cost.