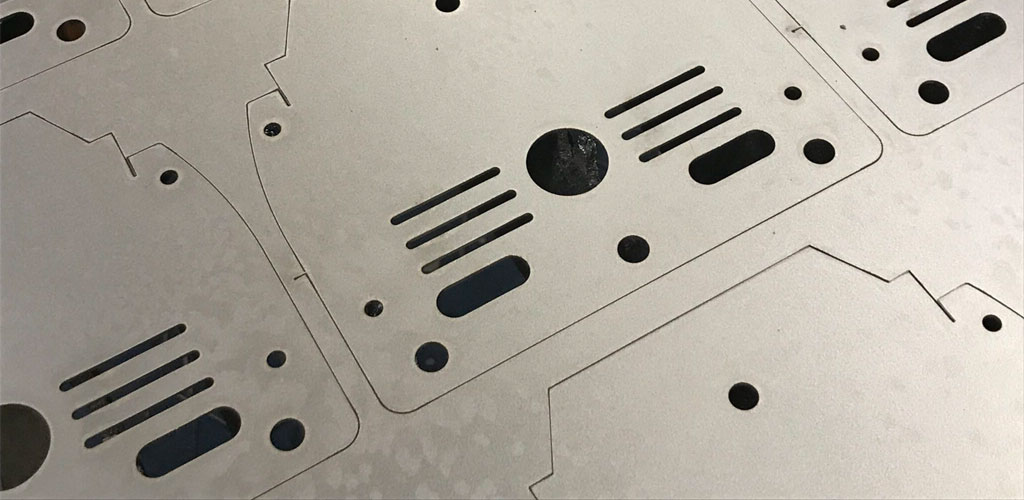

Sheet metal laser cutting is a precise and efficient technique used for cutting various sheet metals into custom shapes and sizes. This process uses a high-powered laser beam to cut through materials like mild steel, stainless steel, iron, aluminum, and other metals.

While laser cutting offers accuracy, quality, and the ability to handle complex designs, the cost of laser cutting can vary significantly based on several factors.

In this article, we will break down the key factors that influence the price of sheet metal laser cutting and provide insights into the costs of different materials.

7 Key Factors Affecting Sheet Metal Laser Cutting Prices

The cost of sheet metal laser cutting is influenced by several factors, including the material type, thickness, cutting complexity, volume, labor cost, post-cutting operations, and more.

Let’s take a look at the most important factors that affect the final price:

1. Material Type and Thickness

Different metals have varying costs, with materials like aluminum and stainless steel typically being more expensive than mild steel or iron. Thicker metal sheets require more power to cut and thus increase the cost.

Material | Thickness (mm/inches) | Price Range ($/kg or $/lb) |

Iron | 2.0 mm (0.079 in) | $0.30–$0.80/kg ($0.14–$0.36/lb) |

Mild Steel | 1.0 mm (0.039 in) | $0.50–$1.00/kg ($0.23–$0.45/lb) |

Stainless Steel | 1.5 mm (0.059 in) | $1.50–$3.00/kg ($0.68–$1.36/lb) |

Aluminum | 2.0 mm (0.079 in) | $2.00–$4.00/kg ($0.91–$1.81/lb) |

Additional factors like sheet size and special coatings, can also affect the price. A standard 4×8 ft (1.2×2.4 m) mild steel sheet, 2 mm thick, can cost approximately $60–$120.

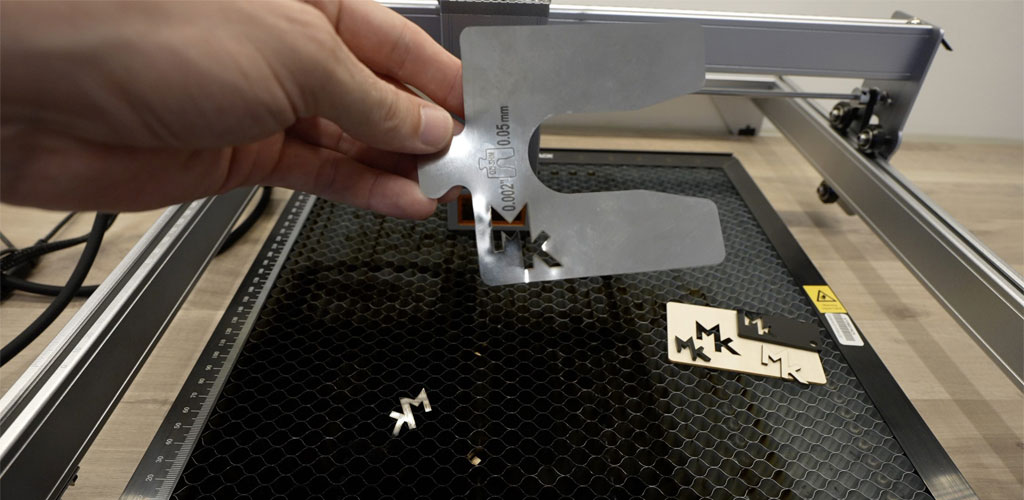

2. Design Time

The complexity of the design determines the cost of preparing the CAD file for laser cutting. Our designers typically charge $20–$100/hour based on their expertise.

Design Type | Time Required | Cost ($) |

Simple shapes | 1 hour | $20–$100 |

Complex geometries | 2–4 hours | $40–$400 |

Custom prototypes | 5+ hours | $100–$500+ |

3. Laser Cutting Time

Laser cutting costs are often calculated based on cutting speed, material type, and thickness. Machines typically charge an hourly rate:

- Hourly Rate: $60–$150/hour

- Cutting Speed: 1–20 m/min (3.3–65.6 ft/min) depending on material and laser power.

Example: Cutting a 1-meter (39.37-inch) straight line on a 2 mm (0.079 in) thick mild steel sheet:

- Speed: 12 m/min (39.4 ft/min)

- Time: 5 seconds

- Cost: $0.083–$0.21 per meter ($0.025–$0.064 per foot).

Complex designs with intricate details will require slower speeds and additional time, increasing the cost.

4. Setup and Labor

Setup time involves positioning the material, calibrating the laser cutter, and performing initial tests. This can take 15–30 minutes, with labor rates ranging from $20–$50/hour.

Task | Time (mins) | Cost ($) |

Material setup | 10–15 | $3.33–$12.50 |

Calibration | 5–10 | $1.67–$8.33 |

Testing | 5–10 | $1.67–$8.33 |

Total | 20–30 | $6.67–$29.17 |

Larger orders or high-volume production may result in discounts, but custom small batches typically cost more per unit.

5. Volume

The volume of parts being cut directly affects the overall cost:

- Small Volume: Single or low-quantity orders may incur higher per-part costs due to setup times and material waste. Cutting 10 parts may cost $10–$15/part.

- Large Volume: Bulk orders benefit from economies of scale. Setup and design costs are spread across the total quantity, significantly reducing the cost per part. Cutting 1,000 parts may reduce the cost to $1–$3/part.

High-volume orders might also qualify for material discounts or batch processing, further lowering costs.

6. Lead Time

Lead time influences the cost, shorter lead times require more urgent work, which may come at a premium.

- Standard Lead Time: 3–7 business days, no additional charges.

- Expedited Lead Time: 1–2 business days, with a 20%–50% surcharge.

- Example: For a $500 order, expedited service could add $100–$250.

If the provider must prioritize your project or work overtime, the surcharge can be even higher.

7. Post-Cutting Operations

Post-cutting operations such as deburring, polishing, sheet metal bending, or painting can add significant costs:

- Deburring: $5–$15/hour, depending on part complexity.

- Polishing: $10–$25/hour.

- Bending: $0.50–$5 per bend.

- Painting/Coating: $10–$50/m² ($0.93–$4.65/ft²).

Example: A 1 m² (10.76 ft²) laser-cut part with deburring and painting:

- Deburring: 1 hour = $10

- Painting: $20

- Total: $30

4 Common Sheet Metal Laser Cutting Price

1. Mild Steel Sheet Laser Cutting Price

Mild steel is one of the most commonly used materials in sheet metal laser cutting. Prices for mild steel sheet cutting can range between $0.10 to $0.60 per inch ($3.94 to $23.62 per meter) depending on various factors.

- 1mm (0.039″) thickness: Around $0.12 per inch ($4.72 per meter)

- 6mm (0.24″) thickness: Around $0.30 per inch ($11.81 per meter)

2. Stainless Steel Sheet Laser Cutting Price

Stainless steel is a more expensive material due to its durability, corrosion resistance, and strength. Prices for cutting stainless steel sheets generally range between $0.15 to $1.00 per inch ($5.91 to $39.37 per meter).

- 1mm (0.039″) thickness: Around $0.20 per inch ($7.87 per meter)

- 5mm (0.20″) thickness: Around $0.60 per inch ($23.62 per meter)

3. Iron Sheet Laser Cutting Price

Iron sheets are less common in laser cutting but can still be used in certain applications. The cost for cutting iron sheet typically falls between $0.12 to $0.50 per inch ($4.72 to $19.69 per meter), depending on thickness and complexity.

- 1mm (0.039″) thickness: Around $0.14 per inch ($5.51 per meter)

- 10mm (0.39″) thickness: Around $0.40 per inch ($15.75 per meter)

4. Aluminum Sheet Laser Cutting Price

Aluminum is a lightweight and versatile metal widely used in industries like aerospace, automotive, and electronics. The laser cutting price for aluminum sheet typically ranges between $0.12 to $0.80 per inch ($4.72 to $31.49 per meter).

- 2mm (0.079″) thickness: Around $0.15 per inch ($5.91 per meter)

- 6mm (0.24″) thickness: Around $0.40 per inch ($15.75 per meter)

Conclusion

The cost of sheet metal laser cutting depends on a range of factors, from the material type and thickness to the complexity of the design and the order size.

At our company, we deliver competitive pricing without compromising on precision and quality in our laser cutting services.

Contact us today for a custom quote based on your project requirements!