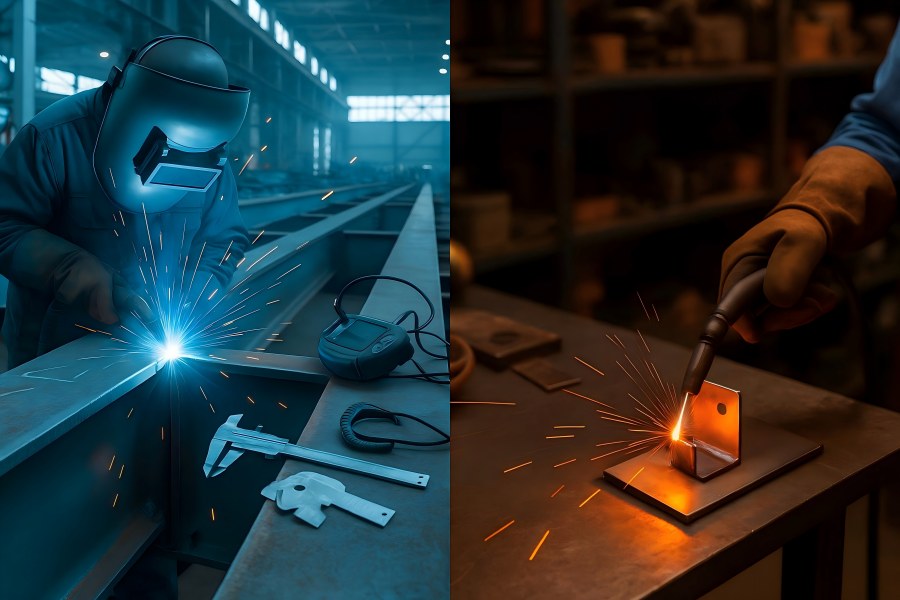

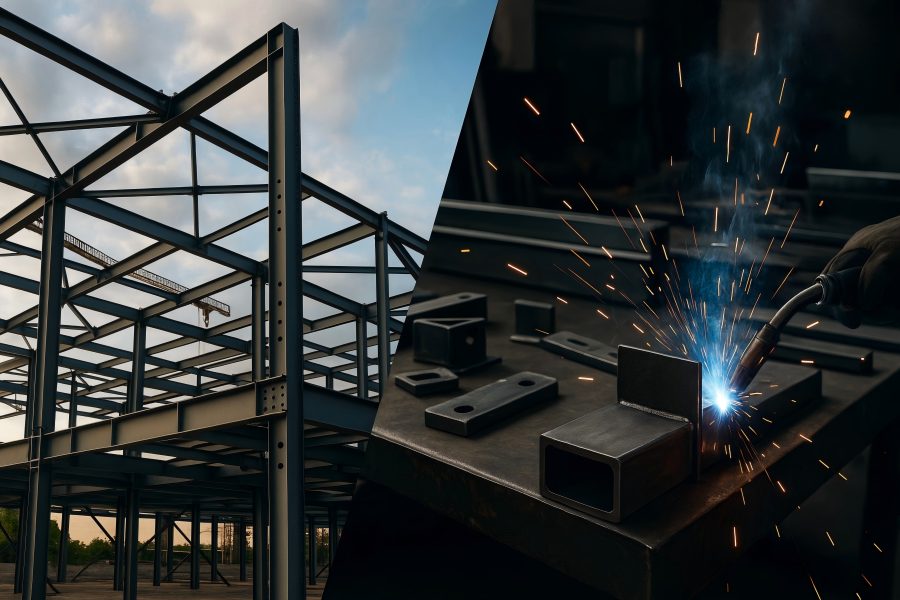

Structural and “standard” welding reflect different intent levels. Structural welding is engineered to carry defined loads for decades, using codes, qualified procedures, and rigorous inspection. Standard welding covers routine, non-critical work with limited loads, low failure risk, and minimal documentation.

This article explains the boundary between them and how it affects quality, schedule, and cost.

What Structural Welding Means

Structural welding is performed on parts of a structure that must safely transfer loads (dead load, live load, wind, seismic, fatigue) with controlled reliability.

Typical examples include building frames, bridges, offshore modules, heavy lifting frames, transmission towers, and safety-critical supports.

Governing Codes and Conformance

Structural welds are specified against comprehensive codes and standards. Common frameworks include AWS D1.1 (steel), D1.2 (aluminum), D1.5 (bridge welding), AISC 360/341 for structural design and seismic detailing, and EN 1090 or ISO 3834 families in Europe. Job specs often add project-specific acceptance criteria, traceability, and documentation retention.

Loads, Reliability, and Consequence Of Failure

Designers calculate stresses and detail joints (e.g., fillet size, groove geometry, backing, run-off tabs) to handle ultimate and fatigue loads with known safety factors. Because failure can endanger life, structural welding requires procedure qualification (PQR), qualified welders (WPQ), and defined NDE coverage.

What Standard Welding Means

“Standard welding” here refers to routine fabrication and repair where loads are modest and the impact of failure is low: guards, trays, housings, brackets, ducting, consumer products, prototypes, jigs and fixtures, or non-load-bearing architectural elements.

Typical Use Cases

Shops use standard welding to build parts to print with functional and cosmetic requirements, but without the heavy design calculations and inspection burdens of structural work. Fit-for-purpose is the benchmark: joints must be sound and meet dimensional tolerances, but long-term cyclic performance under seismic or fatigue regimes is rarely a design driver.

Process Flexibility and Tolerance

Standard jobs often prioritize speed and versatility (e.g., GMAW/MIG with short-circuit transfer on thin sheet, FCAW for quick deposition on mild steel, or GTAW for cosmetics). Documentation is lighter: a WPS may be used, but full PQRs and third-party witnessing are uncommon unless the client demands them.

Key Differences at A Glance

The values below are typical ranges from industry practice. Always verify with your project specifications.

| Dimension | Structural Welding | Standard Welding |

| Primary objective | Safely carry design loads over service life | Functional assembly, appearance, and basic strength |

| Design basis | Calculated per structural codes; fatigue and seismic considered | General engineering judgment; rarely fatigue-rated |

| Typical codes | AWS D1.x, AISC, EN 1090, ISO 3834 | General AWS/ISO process guidance; customer specs |

| Procedure control | Formal WPS + PQR; essential variables locked | WPS may exist; PQR often not required |

| Welder qualification | Per code (e.g., AWS D1.1 positions/processes) | Shop quals or experience-based signoff |

| Materials | Structural steels (A36, A572, S355, etc.); often impact-tested grades | Wider variety; including sheet, formed parts, misc. alloys |

| Joint detailing | Detailed symbols; prequalified or engineered joints | Simplified symbols; fabricator’s standard details |

| NDE coverage (typical) | 10–100% depending on category and risk | 0–10% (mostly visual inspection) |

| Acceptance criteria | Tight: limits on undercut, porosity, fusion, cracks (zero-tolerance) | Practical: cosmetic + function; cracks rejected |

| Traceability | Heat numbers, filler batch, welder IDs recorded | Limited or none unless specified |

| Documentation retention | Long-term (project lifetime or 5–10 years common) | Minimal; kept to satisfy purchase order |

| Environmental controls | Controlled preheat/interpass; weather limits for field work | As-needed for quality; fewer formal limits |

| Rework handling | NCRs, root-cause analysis, corrective actions | Local repair per shop practice |

| Typical cost impact | Higher—engineering, inspection, documentation | Lower—faster throughput, fewer formalities |

Design and Engineering Implications

Joint Design and Detailing

Structural joints are selected to manage load paths and weld shrinkage. Designers choose complete-joint-penetration (CJP) groove welds where full strength is required, partial-joint-penetration (PJP) or fillet welds elsewhere, and add run-off tabs to ensure full throat at terminations.

Standard welding uses fillets and simple grooves optimized for manufacturability and fit-up speed.

Distortion and Restraint Strategies

Because member alignment impacts global stability, structural work emphasizes sequence planning, balanced welding, and fixtures to limit distortion.

Standard jobs also combat distortion but can accept slightly looser flatness or angularity if the function isn’t compromised.

Material Selection and Heat Input Control

Structural applications may require notch toughness (CVN), low hydrogen practice, and controlled heat input to protect HAZ toughness and avoid lamellar tearing.

In standard work, heat input is still managed for cosmetics and strength but rarely tied to formal limits.

Quality Assurance and Inspection Regimes

Procedure and Welder Qualification

Structural welding locks “essential variables” (process, filler, position, base metal group, preheat/interpass, current/polarity). Changes force requalification. Welders must demonstrate proficiency in the applicable process, position, and thickness.

Standard welding relies on shop-level competency; formal requalification is less frequent.

NDE Coverage and Acceptance Levels

Structural jobs often mandate a mix of visual (VT), magnetic particle (MT), dye penetrant (PT), ultrasonic (UT), and radiographic (RT) examinations with specified percentages per joint category.

Standard welding nearly always includes VT; MT/PT are added for critical aesthetics or leakage, while UT/RT are rare.

Documentation, Traceability, and Auditability

Structural projects track heat numbers, consumable lots, welder IDs, calibrated equipment, and inspection sign-offs, creating an auditable record.

Standard projects keep travelers, in-process checks, and final inspection reports as required by the client.

Execution In The Shop and Field

Preheat, Interpass, and Environmental Controls

For structural steel, preheat reduces hydrogen cracking risk, and interpass temperature controls protect toughness. Field work adds weather limitations (wind, rain, temperature).

Standard welding may apply preheat for thick or hardenable steels but with fewer formal checks.

Fit-Up, Tolerances, and Sequencing

Structural fit-up tolerances aim to protect load paths and ensure connection geometry for bolts, gussets, and bracing lines. Sequencing reduces locked-in stresses and distortion.

Standard welding prioritizes smooth assembly flow and final dimensions that meet the drawing.

Rework Handling and Root-Cause Analysis

Structural rework triggers non-conformance records (NCRs), documented repairs, and sometimes engineering assessments.

Standard rework is addressed locally; only significant defects escalate.

Indicative Productivity and Cost Data

Deposition rates, travel speeds, and costs vary with joint size, position, shop vs. field, and region. Figures below represent typical shop conditions on carbon steel with competent operators.

| Process | Shielding | Typical Deposition Rate (kg/h) | Typical Travel Speed For 8 mm Fillet (mm/min) | Typical All-In Cost Per Meter (Standard) USD | Typical All-In Cost Per Meter (Structural) USD |

| SMAW (Stick) | Coated electrode | 1.0–3.0 | 80–150 | 12–25 | 18–35 |

| GMAW (MIG, Short-Circuit/Spray) | Gas (CO₂/Mix) | 3.0–8.0 | 300–600 | 8–20 | 15–30 |

| FCAW (Gas-Shielded) | Gas | 4.0–10.0 | 200–350 | 10–22 | 18–35 |

| SAW (Submerged Arc) | Flux | 6.0–15.0 | 400–1000 | 9–18 | 16–32 |

| GTAW (TIG) | Gas (Ar) | 0.5–2.0 | 60–120 | 15–35 | 22–45 |

Why structural numbers are higher: extra fit-up checks, preheat/interpass recording, inspector hold points, NDE, consumable control, and documentation time all add to the per-meter cost—even when the arc time is identical.

Cost, Schedule, and Risk

Cost Drivers

- Engineering and detailing: Joint selection, weld sizing, and sequencing add up-front hours.

- Qualification: WPS/PQR testing, welder tests, and third-party witnessing.

- Inspection/NDE: Technician time, access prep, and potential repairs.

- Controls: Preheat equipment, calibrated instruments, consumable storage (ovens for low-hydrogen electrodes), weather shelters.

- Administration: Traceability, document control, turnover dossiers.

Schedule Impacts

Hold points for inspection and NDE can extend cycle time, especially for thick CJP groove welds awaiting UT/RT clearance. Field structural welding also competes with other trades; weather can create delays. Standard welding moves faster with fewer external dependencies.

Risk Reduction Tips

- Lock the WPS envelope early (process, filler, heat input).

- Use prequalified joints where allowed to avoid unnecessary PQRs.

- Plan access for NDE; a beautiful weld you can’t UT is a problem.

- Sequence to minimize distortion and cumulative restraint.

- Perform mock-ups for complex joints or tight tolerances.

Data Snapshot: Inspection and Acceptance

| Item | Structural Welding | Standard Welding |

| Visual inspection coverage | 100% | 100% |

| MT/PT coverage (typical) | 10–50% of selected categories | 0–10% on critical surfaces |

| UT/RT coverage (typical) | 10–100% of CJP/fatigue-critical | Rare; only by exception |

| Common acceptance (examples) | No cracks; limited undercut and porosity; fusion verified by NDE where required | No cracks; cosmetic and functional criteria per PO |

| Recordkeeping | Welder IDs, heat numbers, WPS, PQR, NDE reports | Final inspection record; limited traceability |

Note: Specific numeric limits (e.g., undercut depth, porosity distribution) are defined by the governing code and project spec.

When To Specify Structural Welding

Choose structural welding when any of the following apply:

- Load-bearing members or joints with quantified design loads.

- Fatigue, impact, or seismic demands (bridges, cranes, frames).

- Life safety implications of failure.

- Jurisdictional requirements mandate code compliance (e.g., building authorities).

- The owner’s risk posture is conservative for critical assets.

If none apply and the part’s function is non-critical, standard welding—with appropriate workmanship criteria—often delivers better lead time and cost.