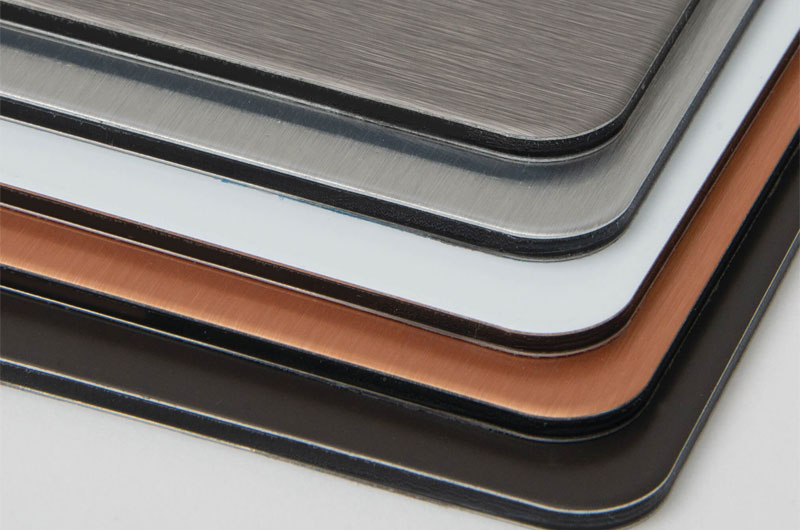

Composite sheet metals, such as aluminum composite panels (ACP), copper composite materials (CCM), and steel-polymer laminates, are increasingly used in automotive, aerospace, construction, and signage industries due to their lightweight properties, strength, and corrosion resistance.

However, cutting composite sheet metals presents unique challenges due to the combination of metal and non-metal layers, adhesive cores, and thin profiles. Improper cutting can lead to delamination, burring, edge chipping, and tool wear.

This article provides practical tips and best practices for cutting composite sheet metals effectively and safely, ensuring clean edges, precision, and extended tool life.

1. Understand the Composite Structure

Before choosing a cutting method or tool, it’s critical to understand the structure of the composite sheet. An aluminum composite panel typically features two thin aluminum layers bonded to a polyethylene or fire-resistant inner core. Cutting such materials involves penetrating both metal and plastic layers simultaneously, which behaves differently than solid metals.

Key properties to identify:

- Metal layer thickness

- Core material type (PE, FR, or mineral-filled)

- Overall panel thickness

- Surface coatings (e.g., PVDF, powder coat)

Knowing this helps you choose the correct cutting technique and avoid damaging the layers.

2. Select the Right Cutting Tools

Tool selection plays a significant role in producing clean, accurate cuts in composite sheet metals. The goal is to minimize heat generation and mechanical stress that can cause delamination or melting of the core.

Manual Tools (For Small Jobs or On-Site Trimming):

- Utility Knife: Suitable for thin panels with soft cores (e.g., PE core).

- Hand Shears or Snips: Good for light-duty work but can deform edges.

- Scoring Knife: Ideal for straight cuts; score the surface and snap.

Power Tools:

- Circular Saw: Use carbide-tipped blades with fine teeth (e.g., triple chip grind – TCG) designed for aluminum or laminates.

- Router: Useful for creating grooves or decorative edges; ensure bits are sharp and made for composite materials.

- Jigsaw: Equipped with bi-metal blades; ideal for curves or cut-outs.

- CNC Router: Offers the highest precision and speed for mass production with programmable patterns.

Tip: Always use sharp blades and change them regularly to prevent tearing or edge fraying.

3. Use the Appropriate Cutting Speed and Feed Rate

High speeds and incorrect feed rates can overheat the composite material, especially if it has a thermoplastic core. Overheating may result in:

- Melting of the inner core

- Blade gumming

- Warped or discolored edges

Recommendations:

- Moderate Cutting Speed: Reduce the RPM for thick or heat-sensitive panels.

- Consistent Feed Rate: Maintain steady motion to avoid localized heat buildup.

- Avoid Overfeeding: For CNC routers, avoid aggressive feed rates that can break the surface coating.

Always consult the tool manufacturer’s guide for specific speed/feed rate combinations based on material and blade type.

4. Prevent Delamination and Burring

Composite materials are susceptible to delamination, where layers separate at the cut edge due to poor tooling or excessive mechanical stress. Burring is another common issue, especially with aluminum surfaces.

Solutions:

- Use down-cut spiral router bits to reduce upward lifting forces.

- Use masking tape along the cutting line to minimize chipping and protect the surface from scratches.

- Use a zero-clearance insert on saws to support the sheet during cutting and reduce tear-out.

- Employ scoring before cutting: Pre-score the metal layer to control the fracture path.

5. Secure the Workpiece Properly

Vibration and panel movement during cutting can cause inaccuracies and edge defects. Secure clamping and proper workholding are essential for precision.

Best practices:

- Use vacuum tables or clamps when routing or sawing.

- Ensure the panel is fully supported on a flat surface.

- For CNC machines, avoid excessive pressure that could dent soft cores.

If the sheet is unsupported, it can flex under the tool pressure, causing uneven edges and potential tool damage.

6. Coolants and Dust Collection

Cutting composite sheet metals generates heat and dust. The metal layers can spark, while the core materials may produce plastic dust or fumes.

Use cooling and extraction systems:

- Compressed air or mist coolants can reduce heat buildup and prolong tool life.

- Employ dust collectors or vacuum attachments to remove debris, especially when working indoors or with CNC routers.

- Ensure ventilation when cutting panels with thermoplastic cores to avoid inhaling fumes.

Always wear PPE: eye protection, gloves, dust mask, and hearing protection.

7. Finish the Edges

After cutting, edges may need finishing, especially for visible installations or parts that require assembly.

Edge finishing techniques:

- Deburring tools: Manual or rotary burr removers work well for metal layers.

- File or sandpaper: Smooth rough plastic cores.

- Edge sealing: For outdoor use, sealing the edge with silicone or plastic trim may prevent moisture ingress and corrosion.

Edge finishing also improves safety by eliminating sharp corners.

8. Test Cuts Before Full Production

When working with a new composite material or using a new tool, always run test cuts on scrap pieces. This allows you to fine-tune:

- Cutting depth

- Blade choice

- Feed rate

- Cooling strategy

Testing helps reduce waste and ensures better consistency in final parts.

9. Maintenance and Tool Inspection

Dull or damaged blades not only reduce cutting quality but also increase the risk of delamination and tool breakage.

Routine checks:

- Inspect blade teeth for chipping.

- Replace worn-out router bits.

- Clean resin build-up on blades after use.

Regular maintenance extends tool life and ensures safer operations.

10. Choose the Right Cutting Method Based on Project Needs

Different cutting methods suit different production scales and tolerances:

| Cutting Method | Best Use Case |

|---|---|

| Hand Tools | Small jobs, minor adjustments |

| Circular Saw | Straight cuts, medium-volume jobs |

| CNC Router | High-precision, mass production |

| Waterjet Cutting | No heat distortion, intricate patterns |

| Laser Cutting | Thin panels with clean finish, complex shapes |

For highly engineered applications, such as aerospace or electronics enclosures, CNC or waterjet cutting is often preferred for dimensional accuracy and minimal thermal impact.