Cutting stainless steel presents unique challenges compared to mild steel or aluminum. Its combination of hardness, toughness, and work-hardening characteristics makes it challenging to achieve clean, burr-free cuts without the right tools, techniques, and preparation.

Whether you’re performing laser cutting, plasma cutting, waterjet cutting, or mechanical cutting methods like sawing or shearing, the following tips will help ensure high-quality results with minimal waste and post-processing.

1. Choose the Right Cutting Method for the Application

Different metal cutting methods offer varied results depending on the stainless steel grade, thickness, and desired finish.

- Laser cutting delivers high precision and is well-suited for cutting thin to medium-gauge stainless steel sheets.

- Plasma cutting works well for thicker materials but may require cleanup due to dross formation.

- Waterjet cutting provides a clean, heat-free cut, which is ideal for thicker or heat-sensitive applications.

- Mechanical methods like band saws or shears are suitable for simple straight cuts but can produce burrs or distortion if not properly configured.

Tip: Match the method to your end-use requirements—consider edge finish, heat-affected zones (HAZ), speed, and cost.

2. Use Sharp and Proper Cutting Tools

Worn or inappropriate cutting tools can lead to rough edges, excessive burrs, and increased tool wear. When using mechanical methods like saws, milling, or shears:

- Always use carbide-tipped or high-speed steel blades.

- Ensure blades are well-maintained and sharp.

- Match the tooth pitch to the thickness of the stainless steel—finer teeth for thin sheets, coarser for thicker pieces.

Sharp tools reduce the risk of work hardening and help achieve smooth, accurate cuts.

3. Apply Correct Feed and Speed Settings

Stainless steel is prone to work hardening, which can dull tools and result in poor-quality edges if feed rates and cutting speeds are incorrect.

- Too slow: Causes excessive heat and work hardening.

- Too fast: Shorten tool’s lifespan and raise the likelihood of edge chipping.

For best results, follow manufacturer recommendations or CNC databases for optimal cutting parameters specific to stainless steel grades. Maintain consistent feed and avoid tool pauses.

4. Choose the Right Stainless Steel Grade

Some stainless steels are more cut-friendly than others. For example:

- Austenitic grades (e.g., 304, 316) are tougher and more challenging to cut.

- Ferritic and martensitic grades (e.g., 430, 410) are harder but more brittle.

- Due to their exceptional strength and toughness, duplex stainless steels demand specialized handling during cutting.

Selecting a grade suitable for both the application and cutting method can greatly influence the ease and quality of the cut.

5. Use Quality Coolants or Lubricants

Heat generation is a significant concern when cutting stainless steel. Overheating can discolor the metal, cause thermal distortion, or leave hard-to-remove burrs.

- Use high-quality coolants or cutting oils when using mechanical tools.

- For laser cutting, ensure appropriate gas assist (typically nitrogen) to reduce oxidation.

- Waterjet cutting naturally cools the material, but proper pressure and abrasives are still critical.

Coolants not only prolong tool life but also improve the quality and cleanliness of cuts.

6. Secure the Workpiece Properly

Movement during cutting can cause jagged edges or misalignment, particularly with thin sheets or tubes.

- Always clamp or fixture the stainless steel securely before starting the cut.

- Use vibration-damping setups for mechanical saws or routers.

- Avoid excessive pressure that may distort or scratch the surface.

A stable workpiece allows for greater control and cleaner cuts.

7. Minimize Heat-Affected Zones (HAZ)

Stainless steel loses its corrosion resistance if overheated due to the breakdown of its passive chromium oxide layer.

To reduce HAZ:

- Use proper laser power and cutting speed combinations.

- Use assist gases like nitrogen or argon to prevent oxidation.

- For plasma cutting, consider water-injection torches or underwater cutting tables.

Minimizing HAZ preserves both the mechanical properties and visual appeal of stainless steel.

8. Use Protective Film or Backing Materials

To avoid surface scratches, discoloration, or debris contamination:

- Apply a protective film to the surface before cutting, especially for decorative or visible parts.

- Use non-metallic backing boards during waterjet or mechanical cutting to prevent backside burring or reflection issues in laser cutting.

- Always clean the material before cutting to remove dust, grease, or scale.

Surface protection during cutting reduces the need for secondary finishing processes.

9. Regularly Inspect and Maintain Equipment

Even advanced cutting machines need regular maintenance to ensure accuracy and clean cuts.

- Clean lenses and mirrors in laser cutters.

- Replace worn nozzles in plasma and waterjet machines.

- Check for tool wear in mechanical saws or mills.

- Calibrate equipment to maintain positional accuracy.

Routine inspection minimizes cutting defects and equipment downtime.

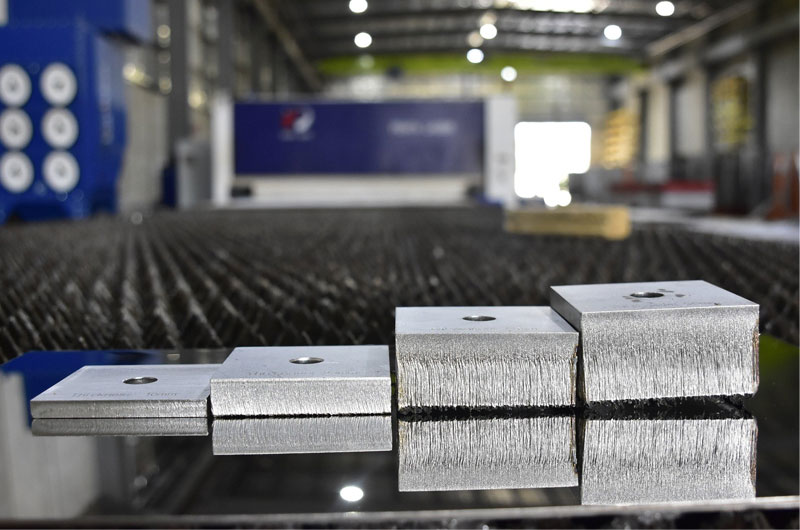

10. Finish Edges with Deburring and Polishing

Even with precision cutting, edges often require some level of post-processing:

- Use grinding wheels, deburring tools, or sanding pads to smooth sharp or uneven edges.

- For high-finish parts, use vibratory tumblers or electropolishing.

- Remove any oxide layers, burn marks, or slag to restore corrosion resistance and improve appearance.

A clean edge not only looks better but also improves safety and functionality in assembled components.