Welding dissimilar metals – joining two different metallic materials is both a challenge and an opportunity in modern manufacturing and repair.

From automotive and aerospace applications to power generation and electronics, engineers often face the need to combine metals with contrasting properties: aluminum to steel, copper to stainless steel, or titanium to nickel alloys.

This article explores the metallurgical hurdles, available techniques, practical considerations, and best practices that make welding dissimilar metals not only possible but, in many cases, economically and technically advantageous.

1. The Metallurgical Challenge

At the heart of the dissimilar-metal welding dilemma lie differences in:

- Melting Point: Aluminum melts at approximately 660 °C, whereas steel begins to melt near 1,500 °C. Heating both to a common molten state risks overheating the lower-melting metal or underfusing the higher-melting one.

- Thermal Conductivity: Copper and aluminum conduct heat efficiently, drawing away weld heat more rapidly than steels or nickel alloys. Inadequate heat retention can prevent proper fusion.

- Coefficient of Thermal Expansion: When metals are heated or cooled, they expand and contract at different rates, which can cause residual stresses, distortion, or even cracking in the joint.

- Solubility and Intermetallic Formation: When two metals dissolve into one another during welding, brittle intermetallic compounds, such as iron aluminides in aluminum–steel welds, can form, severely weakening the joint.

These factors mean that a conventional fusion weld – melting both parent materials together often produces joints plagued by porosity, excessive dilution, cracking, and brittle failure.

2. Welding Techniques for Dissimilar Metals

Several specialized approaches help overcome the innate incompatibility of dissimilar metals:

2.1 Bimetallic Transition Inserts (Explosively or Roll-Bonded)

- Explosive Welding uses a controlled detonation to accelerate one metal plate into another at high velocity, creating a solid-state, metallurgical bond without melting. This produces a graded transition layer, minimizing intermetallic formation.

- Roll Bonding achieves a similar result by passing metal sheets through rollers under high pressure and temperature, fusing them in the solid phase.

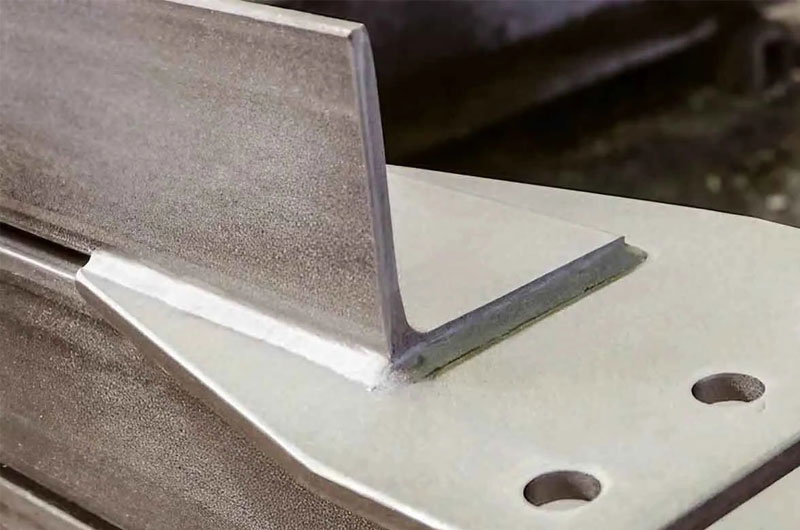

2.2 Filler-Metal Selection (Butter Welding)

Butter Welding deposits an intermediate “buttering” layer of a compatible filler metal onto one substrate before welding the second metal. For example, an aluminum–steel joint might use a nickel-based or iron-aluminum filler to create a graded microstructure that reduces stress and intermetallic formation.

2.3 Cold Welding and Solid-State Joining

- Friction Welding and Friction Stir Welding (FSW) generate heat through mechanical friction without reaching full melting. In FSW, a rotating tool stirs the materials together below the melting point, minimizing defects and producing a fine-grained, defect-free joint.

- Ultrasonic Welding uses high-frequency vibrations under pressure to bond thin cross-sections, commonly used for copper–aluminum electrical interconnections.

2.4 Brazing and Soldering

While not considered true welding, brazing involves using a filler metal with a lower melting point that flows between the base metals and bonds them without melting the bases themselves. Copper-to-steel or aluminum-to-steel brazed joints can achieve good strength and conductivity when properly designed and fluxed.

3. Key Process Considerations

3.1 Preheating and Interpass Temperature

Preheating can reduce thermal gradients and the risk of cracking. For high-carbon steels, preheating to 150–300 °C before buttering with a nickel-based filler helps mitigate hard, brittle microstructures.

3.2 Heat Input Control

Precise heat control – using pulsed welding current, narrow-bead techniques, or automated CNC control minimizes overheating the lower-melting material and reduces dilution.

3.3 Joint Design and Preparation

- Butt vs. Lap Joints: Lap joints can accommodate a butter layer more easily and provide greater surface area, but they may be bulkier.

- Groove Geometry: A carefully engineered bevel and root face allow for complete penetration without excessive dilution.

- Cleanliness: Removing oxides, oils, and contaminants by chemical cleaning or plasma milling is critical, especially for aluminum or titanium.

3.4 Post-Weld Heat Treatment (PWHT)

Thermal cycles after welding, such as stress-relief annealing, help reduce residual stresses, temper martensitic microstructures in steels, and homogenize the joint region.

4. Examples of Dissimilar-Metal Welding

- Aluminum to Steel: Often seen in automotive heat exchangers and battery enclosures. A stainless-steel shim coated with a nickel interlayer is buttered to steel, then aluminum is friction-stir welded to the nickel layer, yielding corrosion-resistant, high-strength joints.

- Copper to Stainless Steel: Common in pressure vessel and piping applications. Tungsten inert gas (TIG) welding with a silver-based filler can join copper tubing to steel ports. Preheating to around 300 °C prevents hot cracking in copper.

- Titanium to Steel: Aerospace and chemical processing sometimes require titanium’s corrosion resistance welded to steel’s high strength. Explosive welding can bond titanium plates to steel backings, followed by conventional welding or machining.

5. Best Practices and Recommendations

5.1 Perform a Feasibility Study

Evaluate mechanical requirements, service environment, and cost-benefit analysis before committing to a dissimilar-metal solution.

5.2 Select the Right Joining Method

- Use solid-state techniques (FSW, friction welding) where minimal intermetallic formation and high fatigue resistance are critical.

- Choose brazing for thin sections or when pressure-tight, leak-proof joints are required.

5.3 Optimize Filler Metals and Transition Layers

Butter weld or use interlayers – nickel, copper, or specialized alloys to create a graded transition zone that accommodates differential expansion and reduces brittleness.

5.4 Implement Rigorous Process Control

Automated clamps, CNC-controlled heat sources, and in-line monitoring ensure repeatable, high-quality joints.

5.5 Plan for Inspection and Maintenance

Specify appropriate non-destructive evaluation (NDE) techniques and protective measures against galvanic corrosion in the design stage.