Our Blogs

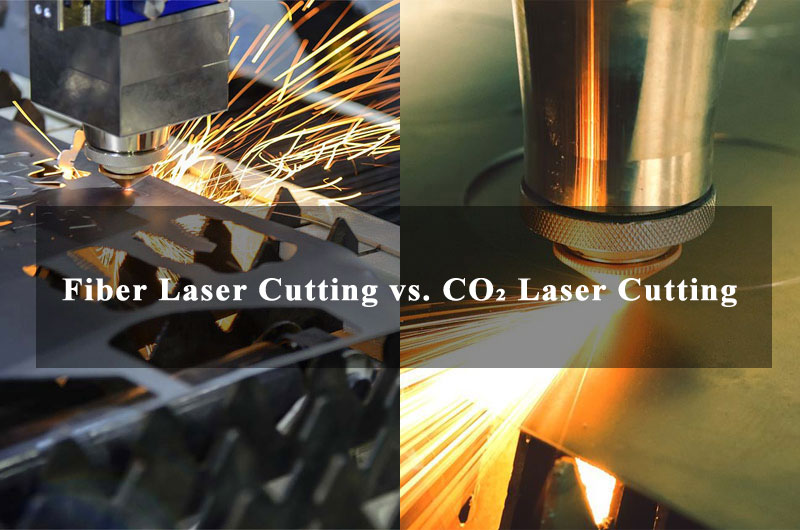

Different cutting technologies, such as laser cutting, plasma cutting, waterjet cutting, and mechanical cutting, have specific limitations and advantages when […]

Laser cutting has revolutionized modern manufacturing by offering precise, efficient, and versatile cutting solutions for metals, plastics, wood, and more. […]

Aluminum sheet cutting is an essential process in numerous industries, including aerospace, automotive, construction, signage, electronics, and manufacturing. However, cutting […]

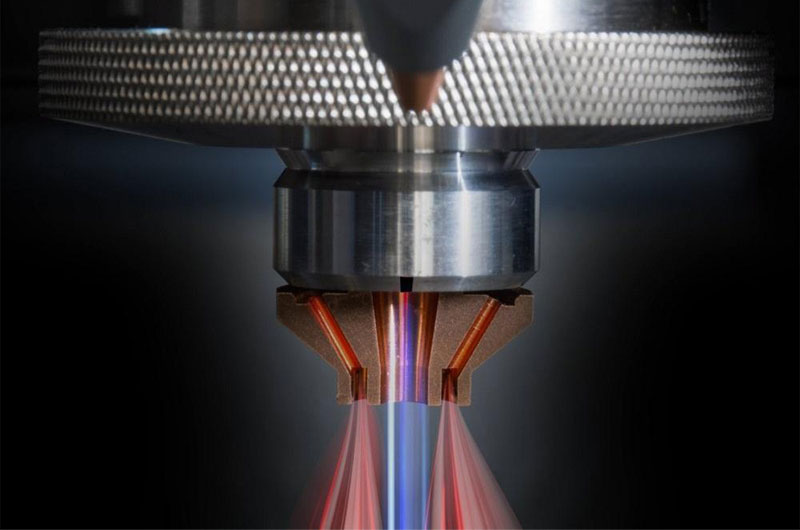

The role of assist gases (typically oxygen, nitrogen, and air) in laser cutting is equally vital in determining cut quality, […]

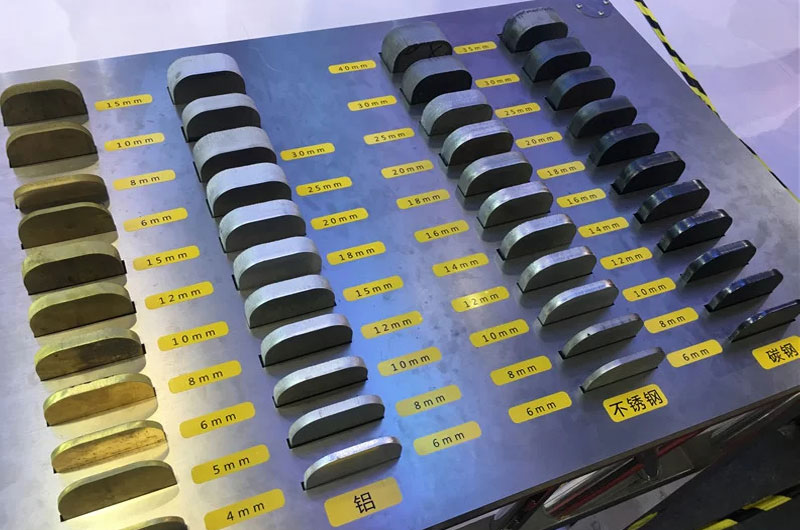

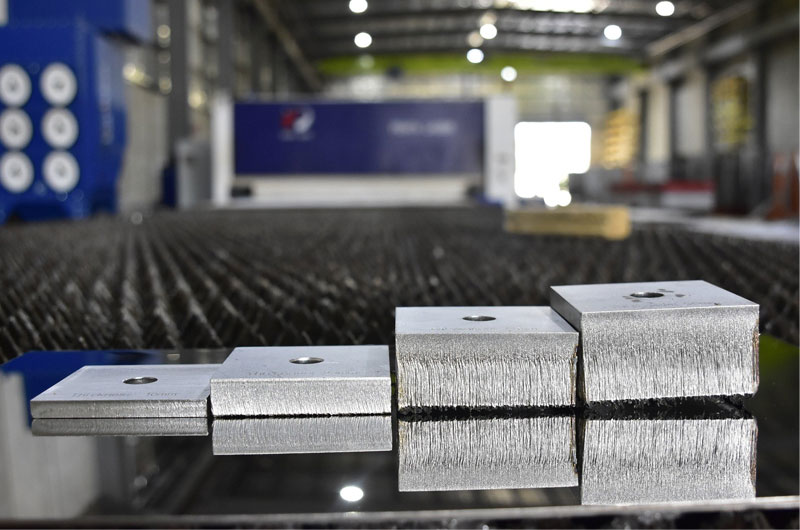

Sheet metal is a fundamental material in manufacturing. One of the critical aspects of working with sheet metal is the […]

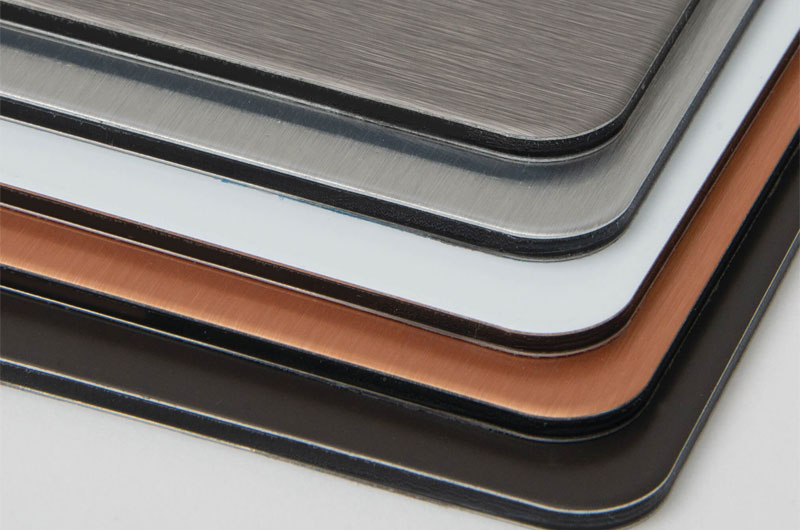

Composite sheet metals, such as aluminum composite panels (ACP), copper composite materials (CCM), and steel-polymer laminates, are increasingly used in […]

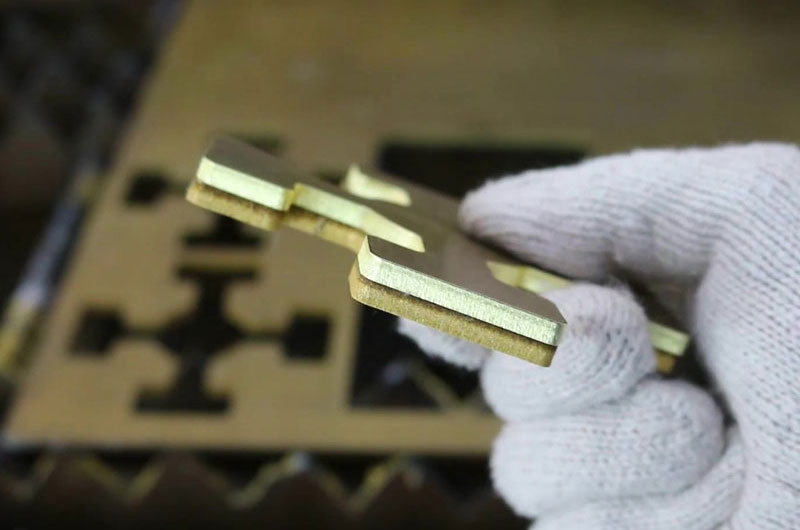

Cutting brass and copper requires careful consideration of their physical properties and the intended application. The choice of cutting method […]

Cutting stainless steel presents unique challenges compared to mild steel or aluminum. Its combination of hardness, toughness, and work-hardening characteristics […]

One key consideration when working with stainless steel, particularly in sheet metal cutting, is how the grade affects cutting performance. […]

In the world of metal fabrication, both stainless steel and mild steel are widely used materials due to their versatility, […]

Galvanized steel often refers to any zinc-coated steel, there are multiple galvanizing methods, most notably hot-dip galvanizing and electro-galvanizing. Understanding […]

Galvanized steel is widely used in construction, HVAC systems, roofing, and sheet metal fabrication due to its superior corrosion resistance […]